Unlocking Precision: The Ultimate Guide to No. 21 Drill Size

When accuracy is paramount, selecting the correct drill bit is crucial. The No. 21 drill size is a specific diameter, essential for creating precisely sized holes for various projects. Whether you’re a seasoned machinist, a dedicated hobbyist, or just tackling a home repair, understanding the nuances of the No. 21 drill size can significantly improve your results. This comprehensive guide will delve into everything you need to know about this versatile drill bit, from its exact dimensions and common uses to best practices and troubleshooting tips, ensuring you achieve professional-quality results every time.

Understanding the No. 21 Drill Bit: Dimensions and Specifications

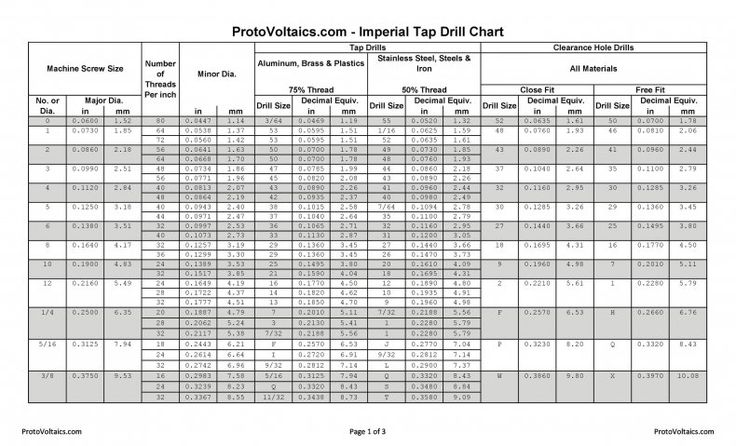

The No. 21 drill bit is part of a numbering system used primarily in the United States to designate drill bit sizes. Understanding its precise dimensions is the first step in using it effectively. The No. 21 drill bit has a diameter of 0.159 inches, which is equivalent to approximately 4.04 millimeters. This specific size makes it ideal for creating holes that are perfectly suited for tapping specific screw sizes or for creating pilot holes for larger drilling operations. Knowing this dimension is essential for ensuring accuracy in your projects.

The numbering system for drill bits ranges from No. 1 (the largest) to No. 80 (the smallest). Each number corresponds to a specific diameter, and the increments between sizes are not uniform. This system is distinct from fractional or metric drill bit sizing, which directly specify the diameter in inches or millimeters, respectively. The No. 21 drill size sits within this spectrum, offering a precise option for intermediate-sized holes. The American National Standards Institute (ANSI) maintains standards for drill bit sizes, including the numbered series, which helps ensure consistency and accuracy across different manufacturers.

Materials Best Suited for a No. 21 Drill Bit

The No. 21 drill bit can be used on a variety of materials, but its effectiveness and longevity depend on selecting the right type of bit and using appropriate drilling techniques. Here’s a breakdown of common materials and best practices:

- Wood: The No. 21 drill bit works well on both hardwoods and softwoods. For clean holes, use a brad-point drill bit, which has a sharp point that helps prevent the bit from wandering.

- Metal: High-speed steel (HSS) drill bits are suitable for drilling into softer metals like aluminum, brass, and copper. For harder metals like steel and stainless steel, consider using cobalt drill bits, which offer superior heat resistance and durability.

- Plastic: The No. 21 drill bit can be used on various types of plastic, including acrylic and PVC. To prevent cracking or chipping, use a slow drilling speed and apply minimal pressure.

- Other Materials: The No. 21 drill bit can also be used on materials like fiberglass and composites, but it’s important to use a sharp bit and appropriate cutting fluids to minimize damage.

Applications of the No. 21 Drill Bit

The No. 21 drill bit’s specific diameter makes it particularly useful in several applications. One of the most common is creating pilot holes for machine screws. Specifically, it’s frequently used as a pilot hole for tapping a 8-32 machine screw. Tapping is the process of creating threads inside a hole so that a screw can be fastened securely. Using the correct pilot hole size is crucial for ensuring a strong, reliable connection.

Beyond tapping, the No. 21 drill bit is also useful in electronics projects where components need to be mounted securely. It can be used for drilling precise holes in circuit boards or enclosures. In woodworking, it can be used for creating pilot holes for small screws or for decorative purposes. The No. 21 drill bit is a versatile tool that can be used in a wide range of projects where precision is important.

Selecting the Right Drill Bit Material for Your Project

Choosing the right drill bit material is just as important as selecting the correct size. Different materials offer varying levels of hardness, heat resistance, and durability, making them suitable for different applications. Here’s a look at some common drill bit materials and their ideal uses:

- High-Speed Steel (HSS): HSS drill bits are a versatile option for drilling into wood, plastic, and softer metals like aluminum. They offer a good balance of hardness and toughness, making them suitable for general-purpose use.

- Cobalt: Cobalt drill bits are made from HSS with an added percentage of cobalt, which increases their heat resistance and hardness. They are ideal for drilling into harder metals like stainless steel and cast iron.

- Titanium Nitride (TiN) Coated: TiN-coated drill bits have a thin layer of titanium nitride on the surface, which reduces friction and increases wear resistance. They are suitable for drilling into a variety of materials and can extend the life of the drill bit.

- Carbide: Carbide drill bits are the hardest and most durable option, making them ideal for drilling into very hard materials like hardened steel and ceramics. They are more expensive than other types of drill bits but offer superior performance and longevity.

Best Practices for Using a No. 21 Drill Bit

To ensure accuracy and prolong the life of your No. 21 drill bit, it’s important to follow best practices for drilling. Here are some tips to keep in mind:

- Use the Right Speed: Drilling speed is crucial for achieving clean holes and preventing damage to the drill bit. For harder materials like steel, use a slower speed. For softer materials like wood, you can use a higher speed. Consult a speed chart for recommended speeds based on the material and drill bit size.

- Apply Consistent Pressure: Apply steady, consistent pressure while drilling. Avoid forcing the drill bit, as this can cause it to break or wander. Let the drill bit do the work.

- Use Cutting Fluid: When drilling into metal, use cutting fluid to lubricate the drill bit and dissipate heat. This will help prevent the bit from overheating and prolong its life.

- Clear Chips Regularly: As you drill, periodically clear away chips from the hole. This will prevent the drill bit from binding and ensure a clean, accurate hole.

- Start with a Pilot Hole: For larger holes, start with a smaller pilot hole to guide the No. 21 drill bit. This will help prevent the bit from wandering and ensure accurate placement.

Troubleshooting Common Issues with No. 21 Drill Bits

Even with the best techniques, you may encounter issues when using a No. 21 drill bit. Here are some common problems and how to troubleshoot them:

- Drill Bit Wandering: If the drill bit is wandering, it may be due to dullness, excessive speed, or uneven pressure. Start by ensuring the bit is sharp. If it’s still wandering, reduce the speed and apply more consistent pressure. Using a center punch to create a starting point can also help.

- Drill Bit Breaking: Drill bits can break if they are subjected to excessive force or heat. Use the correct speed for the material you are drilling, apply consistent pressure, and use cutting fluid to keep the bit cool. If the bit is old or damaged, replace it.

- Rough Holes: Rough holes can be caused by using a dull drill bit or drilling at the wrong speed. Ensure the bit is sharp and use the appropriate speed for the material. Using a backing material can also help prevent tear-out on the back side of the hole.

- Drill Bit Binding: Drill bit binding can occur when drilling deep holes or when drilling into materials that generate a lot of heat. Use cutting fluid to lubricate the bit and periodically clear away chips from the hole. If the bit is still binding, reduce the drilling speed.

The Importance of Sharpness and Maintenance

A sharp drill bit is essential for achieving clean, accurate holes and prolonging the life of the bit. Dull drill bits require more force to cut, which can lead to wandering, breaking, and rough holes. Regularly inspect your No. 21 drill bit for signs of wear and sharpen it as needed. Small bench grinders are very affordable and can easily sharpen a bit. There are also drill bit sharpening tools available that make it easy to maintain a sharp cutting edge.

In addition to sharpening, it’s important to properly store your drill bits to prevent damage. Store them in a drill bit index or case to protect them from dust, moisture, and impact. Applying a light coat of oil to the bits can also help prevent rust and corrosion.

Alternatives to the No. 21 Drill Bit

While the No. 21 drill bit is ideal for many applications, there may be situations where an alternative size is more appropriate. If you need a slightly larger hole, consider using a No. 20 drill bit (0.161 inches). If you need a slightly smaller hole, consider using a No. 22 drill bit (0.157 inches). Alternatively, you can use a fractional or metric drill bit that is close to the desired diameter.

For example, a 5/32 inch drill bit (0.15625 inches) is very close to the size of a No. 21, and can be used if you don’t have the numbered bit on hand. However, always prioritize using the correct size drill bit whenever possible to ensure the best results.

Advanced Techniques: Countersinking and Counterboring

In some applications, you may need to countersink or counterbore the hole created by the No. 21 drill bit. Countersinking is the process of creating a conical depression around the top of the hole, which allows a flat-head screw to sit flush with the surface. Counterboring is the process of creating a cylindrical recess around the top of the hole, which allows a socket-head cap screw to sit flush with the surface.

To countersink or counterbore a hole, you will need a countersink or counterbore tool. These tools are designed to create the desired shape and depth. When using a countersink or counterbore tool, it’s important to use a slow speed and apply consistent pressure. Regularly clear away chips to prevent the tool from binding.

No. 21 Drill Bit: A Reliable Tool for Precision Work

The No. 21 drill size is a crucial component for anyone requiring precise drilling. Its specific dimensions make it ideal for a wide range of applications, from tapping holes for machine screws to creating pilot holes for larger drilling operations. By understanding its specifications, selecting the right materials, and following best practices, you can ensure accuracy and prolong the life of your No. 21 drill bit. Whether you’re a professional machinist or a DIY enthusiast, mastering the use of the No. 21 drill size will undoubtedly enhance the quality and precision of your projects. Keep this guide handy, and you’ll be well-equipped to tackle any drilling task with confidence.