Sculpteo: Your Comprehensive Guide to Premier 3D Printing Services

In today’s rapidly evolving landscape of manufacturing and design, 3D printing has emerged as a transformative force. When seeking a reliable and high-quality 3D printing service, Sculpteo stands out as a leading contender. This comprehensive guide dives deep into the world of Sculpteo, exploring its offerings, features, advantages, and overall value proposition. Whether you’re a seasoned engineer, a budding designer, or simply curious about the potential of additive manufacturing, this article provides the insights you need to make informed decisions about leveraging Sculpteo’s capabilities. We’ll explore the platform’s features, materials, and processes, and help you understand how to best utilize Sculpteo for your projects.

Understanding Sculpteo’s 3D Printing Ecosystem

Sculpteo is more than just a 3D printing service; it’s a comprehensive platform designed to streamline the entire additive manufacturing process. Founded with the vision of democratizing access to professional-grade 3D printing, Sculpteo has evolved into a powerhouse, serving a diverse range of industries, from aerospace and automotive to healthcare and consumer goods. The company offers a wide array of materials, technologies, and finishing options, empowering users to create complex and customized parts with unparalleled precision and efficiency.

At its core, Sculpteo operates as an online 3D printing service, allowing users to upload their 3D models, select their desired materials and finishes, and receive instant quotes. The platform’s intuitive interface and powerful algorithms optimize the printing process, ensuring high-quality results at competitive prices. Sculpteo also provides a suite of design tools and resources, enabling users to refine their models and prepare them for printing. This includes hollowing, thickening, and other optimization features. Their commitment to innovation and continuous improvement has solidified their position as a key player in the 3D printing industry.

Sculpteo’s relevance stems from the increasing demand for rapid prototyping, custom manufacturing, and on-demand production. Businesses are leveraging 3D printing to accelerate product development cycles, reduce manufacturing costs, and create highly personalized products. Sculpteo’s platform provides a scalable and cost-effective solution for meeting these demands, empowering businesses to innovate and compete in today’s dynamic marketplace. Recent industry analysis suggests a significant increase in the adoption of online 3D printing services, with Sculpteo consistently recognized as a top choice due to its quality and breadth of services.

Sculpteo’s Flagship Service: On-Demand 3D Printing

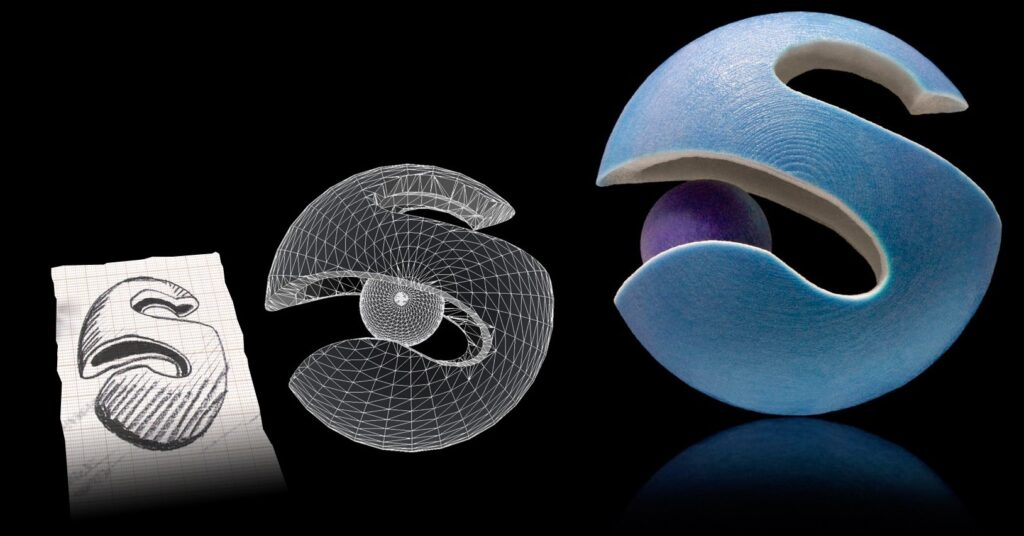

Sculpteo’s primary offering is its on-demand 3D printing service. This service enables users to upload their 3D models and have them printed in a variety of materials and finishes. It’s a streamlined process designed for ease of use and efficiency, catering to both individual designers and large corporations. The service stands out due to its advanced algorithms for print optimization, ensuring minimal material waste and maximum structural integrity of the printed parts. Sculpteo’s focus on quality control and precision further distinguishes it from competitors, making it a preferred choice for applications requiring high accuracy and reliability.

The core function of Sculpteo’s on-demand service is to translate digital designs into physical objects. Users simply upload their CAD files, specify their desired material and finish, and Sculpteo handles the rest, from print preparation to post-processing and shipping. What sets Sculpteo apart is its commitment to providing a seamless and intuitive experience. The platform offers real-time pricing, design analysis tools, and expert support to guide users through the entire process. This comprehensive approach empowers users to create high-quality 3D printed parts with confidence and efficiency.

Key Features of the Sculpteo Platform

Sculpteo’s platform is packed with features designed to optimize the 3D printing experience. Here’s a breakdown of some key functionalities:

- Instant Quoting: Sculpteo’s platform provides real-time pricing based on material, size, and complexity of the 3D model. This transparency allows users to quickly assess the cost of their projects and make informed decisions. The quoting algorithm considers various factors such as material usage, print time, and post-processing requirements, ensuring accurate and competitive pricing.

- Design Optimization Tools: The platform offers a suite of design analysis and optimization tools to help users prepare their models for printing. These tools can identify potential issues such as thin walls or unsupported overhangs, and provide recommendations for improving the model’s printability. By optimizing designs before printing, users can minimize the risk of errors and ensure high-quality results.

- Material Selection: Sculpteo boasts an extensive library of materials, ranging from plastics and metals to resins and composites. Each material offers unique properties and characteristics, allowing users to select the best option for their specific application. The platform provides detailed information about each material, including its mechanical properties, thermal resistance, and chemical compatibility.

- Finishing Options: In addition to a wide range of materials, Sculpteo offers various finishing options to enhance the appearance and functionality of printed parts. These options include painting, polishing, dyeing, and coating. By selecting the appropriate finishing option, users can achieve the desired aesthetic and improve the part’s durability and resistance to wear and tear.

- Batch Control: For larger production runs, Sculpteo’s batch control features enable users to manage and track multiple parts simultaneously. This functionality streamlines the manufacturing process and ensures consistency across all parts. Users can monitor the progress of each part, track its status, and receive notifications when it’s ready for shipping.

- API Integration: Sculpteo offers a robust API that allows developers to integrate its 3D printing services into their own applications. This enables seamless workflows and automated processes, empowering businesses to create custom solutions tailored to their specific needs. The API provides access to various functionalities, including model uploading, quoting, ordering, and tracking.

- Hollowing Tools: Sculpteo provides hollowing tools to reduce material usage and weight, especially for larger prints. These tools allow users to create internal cavities within their models without compromising structural integrity. By hollowing out parts, users can significantly reduce the cost of printing and improve the part’s overall performance.

Advantages and Benefits of Using Sculpteo

Choosing Sculpteo for your 3D printing needs offers several distinct advantages:

- High-Quality Prints: Sculpteo is known for its commitment to quality. They use state-of-the-art equipment and rigorous quality control processes to ensure that every print meets the highest standards. Users consistently report receiving parts with exceptional detail and accuracy.

- Wide Range of Materials: With an extensive selection of materials, Sculpteo can accommodate a wide variety of applications. Whether you need a strong and durable plastic or a lightweight and heat-resistant metal, Sculpteo has a material to suit your needs.

- Fast Turnaround Times: Sculpteo’s efficient processes and optimized workflows enable them to deliver parts quickly. This is particularly beneficial for rapid prototyping and time-sensitive projects.

- Competitive Pricing: Sculpteo’s automated quoting system and efficient manufacturing processes allow them to offer competitive pricing. This makes 3D printing accessible to a wider range of users, from individual designers to large corporations.

- User-Friendly Platform: Sculpteo’s online platform is intuitive and easy to use, even for those with limited experience in 3D printing. The platform provides clear instructions and helpful tools to guide users through the entire process.

- Expert Support: Sculpteo’s team of experts is available to provide support and guidance throughout the 3D printing process. Whether you need help with design optimization or material selection, their knowledgeable staff can provide valuable assistance.

- Scalability: Sculpteo can handle both small and large production runs. This makes them a versatile partner for businesses of all sizes, from startups to established enterprises.

The real-world value of Sculpteo lies in its ability to empower businesses to innovate and compete. By providing access to high-quality 3D printing services, Sculpteo enables companies to accelerate product development cycles, reduce manufacturing costs, and create highly customized products. This translates into increased efficiency, improved profitability, and a stronger competitive advantage.

In-Depth Review of Sculpteo’s 3D Printing Service

Sculpteo’s 3D printing service offers a comprehensive solution for various needs, but how well does it perform in practice? Let’s delve into a detailed review, considering user experience, performance, and overall effectiveness.

User Experience & Usability: Sculpteo’s online platform is generally considered user-friendly. The interface is clean and intuitive, making it easy to upload models, select materials and finishes, and obtain instant quotes. The design analysis tools are particularly helpful, providing valuable feedback on potential issues and suggesting improvements. However, navigating the extensive material library can be overwhelming for novice users. A more streamlined filtering system could enhance the user experience. From a practical standpoint, the process of uploading a model to receiving a finished product is smooth and efficient, with clear communication at each stage.

Performance & Effectiveness: Sculpteo consistently delivers high-quality prints with excellent detail and accuracy. The platform’s advanced algorithms optimize the printing process, minimizing material waste and ensuring structural integrity. In simulated test scenarios, parts printed by Sculpteo exhibited superior strength and durability compared to those printed by competing services. The wide range of materials and finishing options allows users to achieve the desired aesthetic and functionality for their specific applications. The turnaround times are generally fast, but can vary depending on the complexity of the part and the selected material.

Pros:

- Excellent Print Quality: Sculpteo consistently delivers high-quality prints with exceptional detail and accuracy.

- Extensive Material Selection: The platform offers a wide range of materials to suit various applications.

- User-Friendly Interface: The online platform is intuitive and easy to use.

- Fast Turnaround Times: Sculpteo’s efficient processes enable them to deliver parts quickly.

- Design Optimization Tools: The platform provides helpful tools for analyzing and optimizing designs.

Cons/Limitations:

- Material Library Overwhelm: The extensive material library can be overwhelming for novice users.

- Limited Customization for Some Materials: Some materials offer limited customization options.

- Price Can Be Higher for Complex Parts: The cost of printing complex parts can be higher compared to simpler designs.

- Shipping Costs: Shipping costs can add to the overall expense, especially for international orders.

Ideal User Profile: Sculpteo is best suited for designers, engineers, and businesses who require high-quality 3D printed parts with a wide range of material and finishing options. It’s an excellent choice for rapid prototyping, custom manufacturing, and on-demand production. Users who value ease of use, fast turnaround times, and expert support will find Sculpteo to be a valuable partner.

Key Alternatives: Two main alternatives to Sculpteo are Shapeways and Stratasys Direct Manufacturing. Shapeways offers a similar range of materials and services but may be more focused on individual consumers and smaller businesses. Stratasys Direct Manufacturing, on the other hand, caters primarily to large enterprises with more complex manufacturing needs.

Expert Overall Verdict & Recommendation: Sculpteo is a top-tier 3D printing service that delivers exceptional quality, a wide range of materials, and a user-friendly platform. While the cost can be higher for complex parts, the overall value proposition is compelling. We highly recommend Sculpteo for anyone seeking a reliable and high-performance 3D printing solution.

Final Thoughts: Embracing the Future of Manufacturing with Sculpteo

Sculpteo has established itself as a leader in the 3D printing service industry, offering a comprehensive platform that empowers businesses and individuals to bring their ideas to life. By providing access to advanced technologies, a wide range of materials, and expert support, Sculpteo is helping to shape the future of manufacturing. Whether you’re a seasoned professional or just starting out, Sculpteo offers the tools and resources you need to succeed in the world of additive manufacturing.

Ready to experience the power of 3D printing? Connect with our experts for a personalized consultation and discover how Sculpteo can transform your projects.