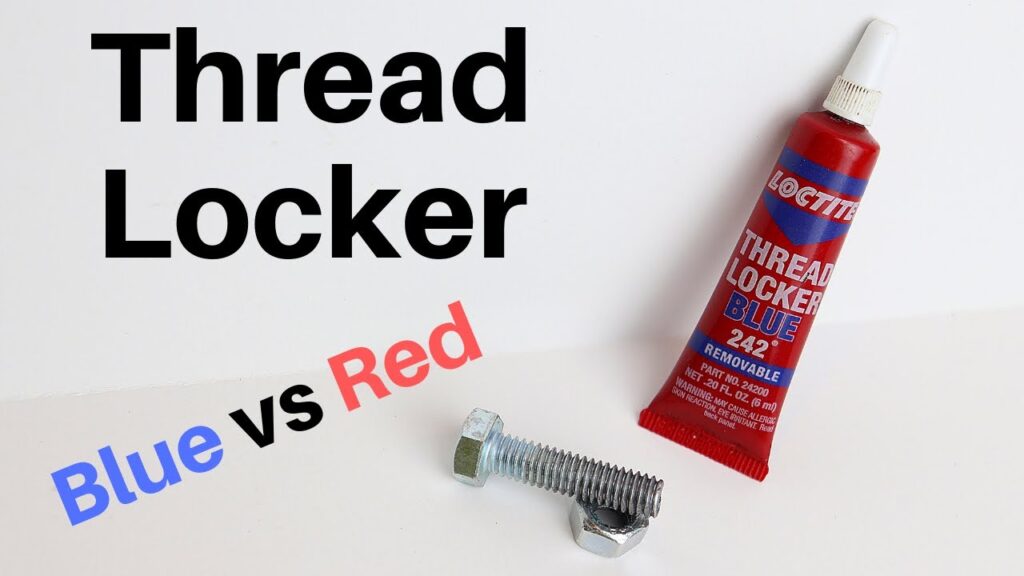

Red Loctite vs. Blue Loctite: A Comprehensive Guide to Threadlockers

Are you grappling with the age-old question of red Loctite vs. blue Loctite? You’re not alone. Choosing the right threadlocker can be the difference between a securely fastened assembly and a frustrating failure. This comprehensive guide delves into the nuances of red and blue Loctite, providing you with the knowledge to make informed decisions for all your fastening needs. We’ll explore their strengths, weaknesses, applications, and everything in between, ensuring you achieve a reliable and long-lasting bond. Our aim is to provide an expert-level understanding, enabling you to confidently select the optimal threadlocker for your specific project.

Understanding Threadlockers: The Basics

Threadlockers, like Loctite, are adhesives applied to the threads of fasteners such as screws and bolts to prevent loosening, leakage, and corrosion. They fill the gaps between the threads, creating a unitized assembly that resists vibration and shock. The choice of threadlocker depends on factors such as the required strength, ease of disassembly, and the materials being joined. Understanding these factors is crucial in the red loctite vs blue debate.

The Anaerobic Advantage

Loctite threadlockers are anaerobic adhesives. This means they cure in the absence of air and in the presence of metal ions. This property ensures that the adhesive only hardens within the threads of the fastener, where air is excluded, and not in the bottle. This controlled curing process is what makes Loctite so effective.

Red Loctite: The Permanent Solution

Red Loctite (Loctite 271 being a common example) is a high-strength threadlocker designed for permanent assemblies. It creates a bond so strong that disassembly typically requires heat and specialized tools. This makes it ideal for applications where fasteners should never come loose, such as critical engine components or heavy machinery. Red Loctite provides excellent chemical and temperature resistance, ensuring long-term reliability in demanding environments. It’s the go-to choice when you need a threadlocker that will stand the test of time.

When to Use Red Loctite

- High-Stress Applications: Situations where vibration or extreme loads could cause fasteners to loosen.

- Permanent Assemblies: Applications where disassembly is unlikely or undesirable.

- High-Temperature Environments: Areas exposed to significant heat, such as engine blocks or exhaust systems.

- Large Fasteners: Bolts and screws larger than 3/4 inch often benefit from the high strength of red Loctite.

The Drawbacks of Red Loctite

The primary disadvantage of red Loctite is the difficulty of disassembly. Attempting to remove fasteners secured with red Loctite without applying heat can damage the fastener or the surrounding components. This can lead to costly repairs and downtime. Therefore, it’s crucial to carefully consider the long-term implications before using red Loctite.

Blue Loctite: The Removable Option

Blue Loctite (Loctite 242 being a common example) is a medium-strength threadlocker designed for fasteners that may need to be disassembled in the future. It provides a secure bond that resists loosening due to vibration, but allows for relatively easy removal with hand tools. Blue Loctite is versatile and suitable for a wide range of applications, making it a popular choice for automotive repairs, machinery maintenance, and household projects. It strikes a balance between holding power and ease of disassembly. It is often considered the more versatile option when considering red loctite vs blue.

When to Use Blue Loctite

- General Purpose Fastening: Applications where fasteners need to be secure but may require removal for maintenance or repairs.

- Adjustable Components: Situations where fasteners may need to be loosened or tightened periodically.

- Small Fasteners: Bolts and screws smaller than 3/4 inch often benefit from the medium strength of blue Loctite.

- Vibration-Prone Environments: Areas subject to moderate vibration, such as machinery or vehicles.

The Limitations of Blue Loctite

While blue Loctite offers a good balance of strength and removability, it’s not suitable for high-stress applications where fasteners are subjected to extreme loads or temperatures. In these situations, the bond may not be strong enough to prevent loosening. Additionally, blue Loctite may not provide adequate chemical resistance in harsh environments.

Loctite 242: A Closer Look at the Versatile Blue Threadlocker

Loctite 242 is arguably the most popular blue threadlocker, known for its versatility and ease of use. It’s a medium-strength, removable threadlocker designed to secure fasteners from loosening due to vibration. Its controlled lubricity allows for reliable clamp loads, ensuring consistent performance. Loctite 242 is suitable for a wide range of applications, making it a staple in many workshops and toolboxes.

Key Features of Loctite 242

- Medium Strength: Provides a secure bond that resists loosening but allows for disassembly with hand tools.

- Removable: Fasteners can be easily removed without damaging the threads or surrounding components.

- Controlled Lubricity: Ensures reliable clamp loads for consistent performance.

- Versatile: Suitable for a wide range of applications, including automotive, machinery, and household projects.

- Temperature Resistant: Maintains its properties in temperatures ranging from -65°F to 300°F.

Loctite 271: Examining the High-Strength Red Threadlocker

Loctite 271 is a high-strength, permanent threadlocker designed for critical applications where fasteners must never come loose. Its robust formulation provides exceptional chemical and temperature resistance, ensuring long-term reliability in demanding environments. Loctite 271 is the go-to choice for securing heavy machinery, engine components, and other critical assemblies.

Key Features of Loctite 271

- High Strength: Creates a permanent bond that resists loosening even under extreme loads.

- Permanent: Disassembly typically requires heat and specialized tools.

- Chemical Resistant: Withstands exposure to oils, solvents, and other chemicals.

- Temperature Resistant: Maintains its properties in temperatures ranging from -65°F to 400°F.

- Vibration Resistant: Prevents loosening due to vibration, ensuring long-term reliability.

Red Loctite vs. Blue Loctite: A Head-to-Head Comparison

The ultimate decision between red Loctite vs. blue Loctite hinges on the specific requirements of your application. Here’s a detailed comparison to help you make the right choice:

| Feature | Red Loctite (e.g., 271) | Blue Loctite (e.g., 242) |

|---|---|---|

| Strength | High | Medium |

| Removability | Difficult (Requires heat) | Easy (Hand tools) |

| Typical Applications | Critical engine components, heavy machinery | General purpose fastening, automotive repairs |

| Temperature Resistance | Up to 400°F | Up to 300°F |

| Chemical Resistance | Excellent | Good |

The Advantages of Using Threadlockers

Using threadlockers offers several key advantages over traditional fastening methods:

- Prevents Loosening: Threadlockers create a secure bond that resists loosening due to vibration, shock, and thermal expansion.

- Seals Threads: Threadlockers fill the gaps between the threads, preventing leakage of fluids and gases.

- Prevents Corrosion: Threadlockers protect the threads from corrosion by creating a barrier against moisture and contaminants.

- Distributes Stress: Threadlockers distribute stress evenly across the threads, reducing the risk of fastener failure.

- Reduces Wear: By preventing movement between the threads, threadlockers reduce wear and extend the life of the assembly.

Real-World Applications: Where Red and Blue Loctite Shine

Let’s consider some practical examples of when to use red Loctite vs. blue Loctite:

- Red Loctite: Securing the bolts on a connecting rod in an engine, where failure could have catastrophic consequences.

- Red Loctite: Fastening the bolts on a heavy-duty machine tool, where vibration is constant and loosening is unacceptable.

- Blue Loctite: Securing the screws on a motorcycle fairing, where removal may be necessary for maintenance or repairs.

- Blue Loctite: Fastening the bolts on a lawnmower blade, where periodic removal is required for sharpening or replacement.

Expert Tips for Using Loctite Threadlockers

To ensure optimal performance, follow these expert tips when using Loctite threadlockers:

- Clean the Threads: Remove any oil, grease, or dirt from the threads before applying the threadlocker.

- Apply Sparingly: A small amount of threadlocker is sufficient. Over-application can make disassembly difficult.

- Allow Sufficient Cure Time: Allow the threadlocker to cure fully before subjecting the assembly to load.

- Use the Right Threadlocker: Choose the appropriate strength and type of threadlocker for your specific application.

- Consult the Datasheet: Refer to the manufacturer’s datasheet for specific instructions and recommendations.

Loctite Alternatives: Exploring Other Threadlocking Options

While Loctite is a leading brand, several alternatives offer similar threadlocking capabilities. These include:

- Permatex: A well-known brand offering a range of threadlockers, sealants, and adhesives.

- Vibra-TITE: A manufacturer specializing in threadlockers and other industrial adhesives.

These alternatives may offer different formulations or price points, so it’s worth exploring your options to find the best fit for your needs.

Maintaining Secure Fastenings: Understanding Long-Term Reliability

Ultimately, the choice between red Loctite and blue Loctite depends on the long-term reliability you require from your fastened assembly. If the joint needs to withstand extreme conditions and never come loose, red Loctite is the clear choice. However, if future disassembly is a possibility, blue Loctite offers a more practical solution. Remember to consider the specific application, the materials being joined, and the potential for future maintenance when making your decision. With the right threadlocker and proper application, you can ensure a secure and long-lasting bond.