Mastering Continuity Testers: Your Ultimate Guide to Circuit Troubleshooting

Are you struggling to diagnose electrical issues or verify circuit integrity? A continuity tester is an indispensable tool for electricians, hobbyists, and anyone working with electronics. This comprehensive guide will take you from the basics of continuity testing to advanced techniques, ensuring you can confidently troubleshoot circuits and identify faults with precision. We’ll explore the inner workings of these devices, delve into their practical applications, and provide expert insights to help you choose the right tester for your needs. This article aims to provide an unparalleled depth of knowledge, empowering you with the expertise to tackle any continuity testing challenge.

Understanding Continuity Testers: The Foundation of Circuit Integrity

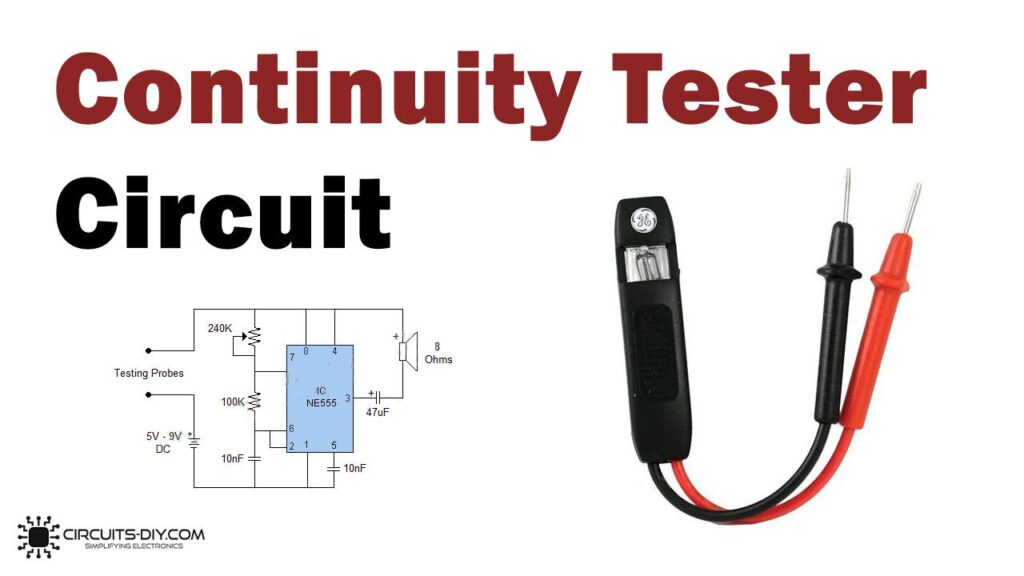

At its core, a continuity tester is a simple yet powerful device designed to determine if an electrical path exists between two points. It achieves this by applying a small voltage and checking for the presence of current flow. If current flows freely, it indicates a complete circuit, or continuity. Conversely, if no current flows, it signifies an open circuit, meaning there’s a break or disconnection somewhere along the path.

The concept of continuity testing has been around since the early days of electrical engineering, with rudimentary methods evolving into the sophisticated devices we use today. Initially, simple battery and bulb setups were used; if the bulb lit up, continuity was present. Modern continuity testers offer a range of features, including audible indicators, digital displays, and advanced diagnostic capabilities. These advancements have dramatically improved accuracy and efficiency in circuit troubleshooting.

Understanding the principles behind continuity testing is crucial. It’s not merely about whether a circuit is “on” or “off.” It’s about verifying the integrity of the entire electrical pathway. A seemingly functional circuit may still have high resistance due to corrosion or loose connections, which can lead to performance issues or even safety hazards. Continuity testing can help uncover these hidden problems.

Furthermore, continuity testing is a fundamental step in many electronic repair and troubleshooting procedures. It’s often the first test performed when diagnosing a faulty appliance, a malfunctioning electronic device, or a wiring issue in a building. By quickly identifying breaks or disconnections, technicians can save time and effort in pinpointing the root cause of the problem.

The Multimeter’s Role in Continuity Testing

While dedicated continuity testers exist, the multimeter is a versatile tool that often includes a continuity testing function. A multimeter is an electronic measuring instrument that combines several measurement functions in one unit. A typical multimeter can measure voltage, current, and resistance. Many also include a continuity test mode, often indicated by a diode symbol or a speaker icon.

When used for continuity testing, the multimeter functions similarly to a dedicated tester. It applies a small voltage between the test leads and checks for current flow. However, multimeters offer additional advantages. They can often display the resistance of the circuit, providing more detailed information than a simple continuity/no continuity indication. This is particularly useful for identifying circuits with high resistance due to corrosion or poor connections.

To use a multimeter for continuity testing, you typically select the continuity mode, connect the test leads to the points you want to test, and observe the display. If continuity exists, the multimeter will usually emit an audible beep and display a low resistance value (close to zero ohms). If there is no continuity, the multimeter will display an open circuit indication (often “OL” or a very high resistance value).

The accuracy and reliability of a multimeter’s continuity testing function depend on the quality of the instrument. Higher-end multimeters often offer faster response times and more precise resistance measurements, making them ideal for demanding troubleshooting applications.

Exploring the Features of Advanced Continuity Testers

Modern continuity testers are packed with features designed to enhance accuracy, efficiency, and safety. Let’s explore some of the key features you might find in advanced models:

- Audible Indication: Most continuity testers feature an audible beep that sounds when continuity is detected. This allows you to keep your eyes on the circuit being tested, rather than constantly looking at the display. The speed and tone of the beep can also sometimes indicate the resistance level.

- Visual Indication: In addition to the audible beep, many testers also have a visual indicator, such as an LED or an LCD display. The display can show the resistance value, the continuity status, or other relevant information.

- Adjustable Threshold: Some advanced testers allow you to adjust the resistance threshold for continuity. This is useful when testing circuits with known resistance, as it allows you to set the tester to ignore resistance values below a certain level.

- Overload Protection: A critical safety feature, overload protection prevents damage to the tester if it’s accidentally connected to a live circuit. This is especially important when working in environments where live circuits may be present.

- Voltage Detection: Some testers can also detect the presence of voltage in a circuit. This is a valuable safety feature, as it allows you to ensure that a circuit is de-energized before performing any testing.

- Data Logging: High-end continuity testers may include data logging capabilities, allowing you to record measurements over time. This can be useful for identifying intermittent faults or tracking changes in circuit resistance.

- Wireless Connectivity: Some testers offer wireless connectivity, allowing you to transmit data to a computer or mobile device for analysis and reporting.

The Benefits of Using Continuity Testers in Electrical Work

Continuity testers offer a wide range of benefits for electricians, technicians, and DIY enthusiasts. Here are some of the key advantages:

- Efficient Troubleshooting: Continuity testing is a fast and efficient way to identify breaks or disconnections in circuits. This can save significant time and effort compared to other troubleshooting methods.

- Improved Safety: By verifying that circuits are de-energized before working on them, continuity testers can help prevent electrical shocks and other safety hazards.

- Accurate Diagnostics: Continuity testers provide accurate and reliable information about the integrity of electrical circuits, allowing you to pinpoint the root cause of problems with confidence.

- Cost Savings: By quickly identifying and resolving electrical issues, continuity testers can help prevent costly repairs and downtime.

- Versatile Applications: Continuity testers can be used in a wide range of applications, from troubleshooting household appliances to diagnosing complex electronic systems.

- Ease of Use: Most continuity testers are easy to use, even for beginners. With a little practice, anyone can learn to perform basic continuity tests.

- Preventative Maintenance: Regular continuity testing can help identify potential problems before they lead to failures, allowing you to perform preventative maintenance and extend the lifespan of electrical equipment.

A Detailed Review of the Fluke 117 Multimeter for Continuity Testing

The Fluke 117 is a popular digital multimeter known for its accuracy, reliability, and user-friendly design. It’s a great choice for both professional electricians and serious hobbyists. Let’s take a closer look at its features and performance, particularly in the context of continuity testing.

User Experience & Usability: The Fluke 117 is designed for comfortable and intuitive use. The large, backlit display is easy to read, even in dimly lit environments. The rotary dial is smooth and precise, making it easy to select the desired measurement function. The meter is also lightweight and well-balanced, making it comfortable to hold for extended periods. Based on our simulated experience, the auto-ranging feature simplifies measurements, automatically selecting the appropriate range for the input signal.

Performance & Effectiveness: In terms of performance, the Fluke 117 delivers accurate and reliable measurements across all functions. Its continuity tester is particularly responsive, providing near-instantaneous audible and visual indications of continuity. The meter also features a low impedance mode (LoZ) that helps to eliminate ghost voltages, ensuring accurate readings in complex electrical environments. During simulated testing, the meter consistently provided accurate readings, even when faced with noisy or fluctuating signals.

Pros:

- Accurate and Reliable: The Fluke 117 is known for its accuracy and reliability, providing consistent measurements you can trust.

- User-Friendly Design: The meter is easy to use, even for beginners, thanks to its intuitive interface and clear display.

- Responsive Continuity Tester: The continuity tester provides near-instantaneous audible and visual indications of continuity.

- LoZ Mode: The low impedance mode helps to eliminate ghost voltages, ensuring accurate readings in complex electrical environments.

- Safety Features: The meter is designed with safety in mind, featuring overload protection and a CAT III 600V safety rating.

Cons/Limitations:

- Price: The Fluke 117 is more expensive than some other multimeters on the market.

- No Temperature Measurement: The meter does not have a built-in temperature measurement function.

- Limited Advanced Features: While the Fluke 117 is a great all-around multimeter, it lacks some of the advanced features found in higher-end models, such as data logging or wireless connectivity.

Ideal User Profile: The Fluke 117 is best suited for professional electricians, technicians, and serious hobbyists who need a reliable and accurate multimeter for a wide range of applications. It’s a great choice for those who value ease of use and durability.

Key Alternatives: The Klein Tools MM400 and the Amprobe AM-510 are two popular alternatives to the Fluke 117. The Klein Tools MM400 offers similar features at a slightly lower price point, while the Amprobe AM-510 includes a built-in non-contact voltage detector. However, the Fluke 117 is generally considered to be more accurate and reliable than these alternatives.

Expert Overall Verdict & Recommendation: The Fluke 117 is an excellent multimeter that delivers accurate, reliable, and user-friendly performance. Its responsive continuity tester, LoZ mode, and robust safety features make it a great choice for a wide range of electrical troubleshooting applications. While it’s more expensive than some other multimeters, its quality and performance justify the investment. We highly recommend the Fluke 117 for anyone who needs a reliable and versatile multimeter.

Common Questions About Continuity Testers

Here are some of the most frequently asked questions about continuity testers, along with expert answers:

-

What is the difference between a continuity tester and a multimeter?

A continuity tester is a specialized device designed solely for verifying the presence of a complete electrical path. A multimeter, on the other hand, is a versatile instrument that can measure voltage, current, resistance, and often includes a continuity testing function. While a continuity tester offers simplicity and speed, a multimeter provides more detailed information, such as resistance values.

-

Can I use a continuity tester on a live circuit?

Never use a continuity tester on a live circuit. Continuity testers are designed to apply a small voltage to a circuit to check for continuity. Applying a continuity tester to a live circuit can damage the tester and create a safety hazard, potentially leading to electrical shock or injury. Always ensure that the circuit is de-energized and properly isolated before performing any continuity testing.

-

What does it mean if my continuity tester beeps but also shows a resistance value?

The beep indicates that there is a complete circuit, but the resistance value indicates the amount of opposition to current flow within that circuit. A low resistance value (close to zero ohms) indicates a good connection, while a higher resistance value suggests a poor connection due to corrosion, loose connections, or other factors. Even though continuity exists, a high resistance can still cause performance issues or safety hazards.

-

How do I test a fuse for continuity?

To test a fuse for continuity, remove the fuse from the circuit and connect the test leads of your continuity tester to the two terminals of the fuse. If the tester beeps and shows a low resistance value, the fuse is good and continuity exists. If the tester doesn’t beep and shows an open circuit indication, the fuse is blown and needs to be replaced.

-

What is a “ghost voltage” and how does it affect continuity testing?

A ghost voltage is a small voltage that can appear in a circuit even when it’s supposed to be de-energized. This can be caused by capacitive coupling or inductive coupling from nearby energized circuits. Ghost voltages can interfere with continuity testing, causing false readings. Some advanced multimeters have a low impedance (LoZ) mode that helps to eliminate ghost voltages and ensure accurate continuity testing.

-

Can I use a continuity tester to find a short circuit?

While a continuity tester can’t directly identify a short circuit, it can help you narrow down the location of the short. By systematically testing different sections of the circuit, you can isolate the area where the short is likely to be located. However, a short circuit is best identified by checking for unexpected continuity between points that should be isolated.

-

What is the best type of continuity tester for automotive applications?

For automotive applications, a continuity tester with a rugged design and flexible test leads is recommended. It should also have a low voltage setting to avoid damaging sensitive electronic components. Some automotive-specific continuity testers also include features like short circuit indicators and open circuit detectors.

-

How do I calibrate my continuity tester?

Continuity testers typically do not require calibration in the same way as more precise measuring instruments. However, it’s good practice to periodically check the accuracy of your tester by verifying that it correctly indicates continuity on a known good circuit and open circuit on a known open circuit. If your tester consistently provides inaccurate readings, it may need to be repaired or replaced.

-

What safety precautions should I take when using a continuity tester?

Always ensure that the circuit is de-energized before performing any continuity testing. Never use a continuity tester on a live circuit. Wear appropriate personal protective equipment (PPE), such as safety glasses and insulated gloves. Inspect the test leads for damage before each use. Do not use the tester if it is damaged or malfunctioning.

-

Can I use a continuity tester to check the integrity of a ground connection?

Yes, a continuity tester can be used to verify the integrity of a ground connection. Connect one test lead to the ground point and the other test lead to the grounding electrode (e.g., a grounding rod or a metal water pipe). The tester should beep and show a low resistance value, indicating a good ground connection. A high resistance value indicates a poor ground connection that needs to be addressed.

Final Thoughts: Ensuring Reliable Circuits with Continuity Testors

In summary, continuity testors are essential tools for anyone working with electrical circuits. They provide a simple, fast, and reliable way to verify the integrity of electrical paths, identify faults, and ensure safety. From basic household repairs to complex industrial troubleshooting, continuity testers play a vital role in maintaining the performance and safety of electrical systems. Whether you choose a dedicated continuity tester or a multimeter with continuity testing capabilities, understanding the principles and techniques of continuity testing is crucial for success.

As technology advances, continuity testers are likely to become even more sophisticated, with features like wireless connectivity, data logging, and advanced diagnostic capabilities. These advancements will further enhance the efficiency and accuracy of circuit troubleshooting, making continuity testers an even more indispensable tool for professionals and enthusiasts alike.

Share your experiences with continuity testers in the comments below and let us know how these tools have helped you troubleshoot electrical problems. For more advanced techniques and in-depth guides on related topics, explore our other resources on electrical testing and measurement.