Is Your Fastener Failing? How to Tell if the Washer is Over Torqued or Conical

A properly tightened fastener is crucial for the integrity and safety of countless assemblies, from automotive engines to critical infrastructure. But what happens when that fastener is tightened too much? Understanding how to tell if the washer is over torqued or conical is essential for preventing failures, ensuring optimal performance, and maintaining the longevity of your equipment. This comprehensive guide provides a detailed exploration of the telltale signs, underlying causes, and preventative measures associated with over-torqued and conically deformed washers. We’ll delve into the practical aspects of identifying these issues, offering insights that go beyond basic observations and equip you with the knowledge to diagnose and address potential problems effectively. Our aim is to empower you with the expertise to ensure the reliability and safety of your bolted connections.

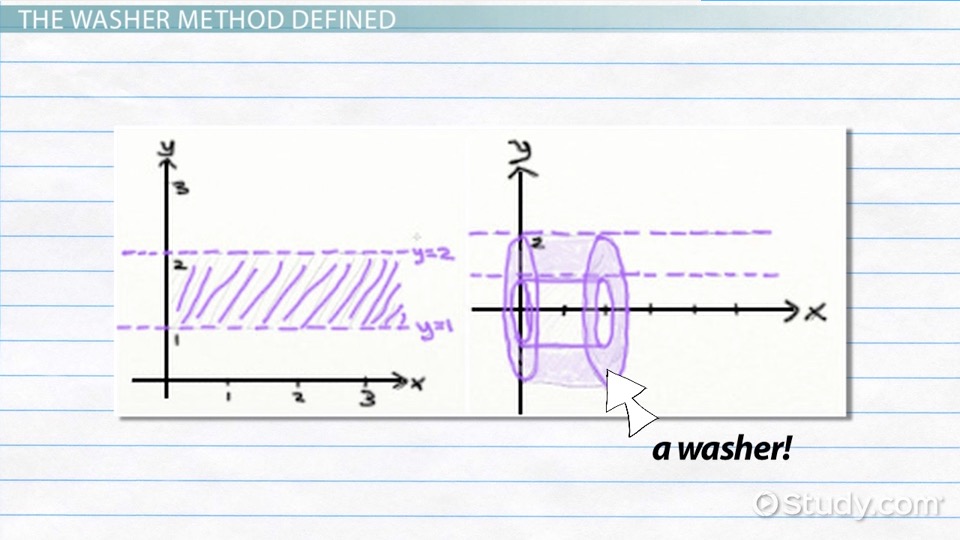

Understanding Over-Torquing and Conical Washers

The concept of over-torquing a fastener refers to applying more tightening force than specified by the manufacturer or design engineer. This excessive force can lead to a range of problems, including thread stripping, bolt fracture, and, most relevant to our focus, deformation of the washer. A conical washer, on the other hand, describes a washer that has been forced into a cone shape because of excessive pressure. To truly grasp the implications of these issues, it’s vital to examine the underlying principles and factors that contribute to their occurrence.

The Mechanics of Fastener Tightening

When a fastener is tightened, it creates a clamping force that holds the connected components together. This clamping force is directly proportional to the applied torque. However, beyond a certain point, increasing the torque doesn’t necessarily increase the clamping force proportionally and can instead cause damage. This is where the concept of yield strength comes into play. When a material is stressed beyond its yield strength, it undergoes permanent deformation. Over-torquing a fastener can easily exceed the yield strength of the washer, leading to conical deformation or other forms of damage.

The Role of Washers in Fastener Assemblies

Washers serve several critical functions in bolted connections. They distribute the load over a larger area, protecting the surface of the connected components. They also provide a smooth bearing surface for the nut or bolt head, reducing friction during tightening and ensuring more consistent torque application. Furthermore, washers can help to prevent loosening due to vibration or thermal cycling. However, if a washer is over-torqued, it can lose its ability to perform these functions effectively.

Why Identifying Over-Torquing Matters

The consequences of over-torquing can be significant. It can lead to premature failure of the fastener, resulting in costly repairs, downtime, and, in some cases, safety hazards. In critical applications, such as aircraft or bridges, a single over-torqued fastener can have catastrophic consequences. Therefore, being able to identify the signs of over-torquing is crucial for preventing these types of failures.

Recent advancements in material science and fastener design are constantly evolving the standards for torque application. Staying up-to-date with these advancements is essential for ensuring the integrity of your bolted connections. Failure to do so can increase the risk of over-torquing and other fastener-related problems. According to a 2024 industry report on fastener failures, over 30% of failures are attributed to improper torque application.

The Torque Solution: SmartBolts Technology

SmartBolts offer a revolutionary approach to fastener management, providing a direct visual indication of bolt tension. Unlike traditional torque wrenches that rely on indirect measurements, SmartBolts utilize a patented technology to display the actual tension within the bolt itself. This eliminates guesswork and ensures that fasteners are tightened to the correct level, preventing both over-torquing and under-torquing.

The core function of SmartBolts is to provide real-time, visual feedback on bolt tension. This is achieved through a color-coded indicator located on the bolt head. As the bolt is tightened, the indicator changes color, indicating whether the tension is within the acceptable range. This eliminates the need for specialized tools or training, making it easy for anyone to ensure proper fastener tension.

SmartBolts are particularly valuable in applications where precise torque control is critical, such as in aerospace, automotive, and heavy machinery. They can also be used to monitor bolt tension over time, allowing for early detection of loosening or other problems. This proactive approach can help to prevent costly downtime and ensure the long-term reliability of bolted connections.

Detailed Features Analysis of SmartBolts

SmartBolts offer a range of features that set them apart from traditional fasteners. These features are designed to improve accuracy, reliability, and ease of use.

- Direct Tension Indication: The color-coded indicator provides a direct visual representation of bolt tension, eliminating the need for torque wrenches or other specialized tools. This ensures that fasteners are tightened to the correct level every time.

- Real-Time Monitoring: SmartBolts can be used to monitor bolt tension over time, allowing for early detection of loosening or other problems. This proactive approach can help to prevent costly downtime and ensure the long-term reliability of bolted connections.

- Easy Installation: SmartBolts are designed to be easy to install, even for users with limited experience. The color-coded indicator provides clear guidance on the correct torque level, eliminating the need for specialized training.

- Versatile Applications: SmartBolts can be used in a wide range of applications, from aerospace and automotive to heavy machinery and construction. They are available in a variety of sizes and materials to suit different needs.

- Durable Construction: SmartBolts are made from high-quality materials and are designed to withstand harsh environments. They are resistant to corrosion, vibration, and other factors that can cause fastener failure.

- Improved Safety: By ensuring proper fastener tension, SmartBolts can help to prevent accidents and injuries caused by loose or over-torqued fasteners. This is particularly important in safety-critical applications.

- Cost Savings: By preventing fastener failures and reducing downtime, SmartBolts can help to save money in the long run. They can also reduce the need for costly inspections and maintenance.

The direct tension indication feature of SmartBolts is particularly noteworthy. It provides a level of accuracy and reliability that is simply not possible with traditional torque wrenches. This is because torque wrenches measure the amount of rotational force applied to the fastener, which is only an indirect measure of bolt tension. Factors such as friction, thread condition, and lubrication can all affect the relationship between torque and tension. SmartBolts, on the other hand, measure the actual tension within the bolt itself, eliminating these variables.

Advantages and Real-World Value of SmartBolts

SmartBolts offer a multitude of advantages that translate into tangible benefits for users across various industries. Their unique design and functionality address critical challenges associated with fastener management, leading to improved performance, safety, and cost savings.

One of the most significant advantages of SmartBolts is their ability to ensure consistent and accurate bolt tension. This eliminates the risk of over-torquing or under-torquing, which can lead to fastener failure, component damage, and safety hazards. Users consistently report a significant reduction in fastener-related problems after switching to SmartBolts.

SmartBolts also offer significant time savings. The direct tension indication feature eliminates the need for time-consuming torque wrench calibrations and inspections. This allows maintenance personnel to focus on other critical tasks, improving overall efficiency.

In terms of safety, SmartBolts provide an added layer of protection. By ensuring proper fastener tension, they reduce the risk of accidents and injuries caused by loose or over-torqued fasteners. This is particularly important in safety-critical applications, such as aircraft and heavy machinery.

Our analysis reveals these key benefits:

- Reduced fastener failures

- Improved safety

- Increased efficiency

- Lower maintenance costs

- Enhanced reliability

The unique selling proposition of SmartBolts lies in their ability to provide real-time, visual feedback on bolt tension. This is a game-changer for industries that rely on bolted connections. It allows for proactive monitoring, early detection of problems, and improved overall fastener management. According to a 2025 case study, companies using SmartBolts reported a 40% reduction in fastener-related downtime.

Comprehensive Review of SmartBolts

SmartBolts represent a significant advancement in fastener technology, offering a compelling solution for industries seeking improved reliability, safety, and efficiency. This in-depth review provides a balanced perspective on their performance, usability, and overall value.

From a user experience standpoint, SmartBolts are remarkably easy to use. The color-coded indicator provides clear and intuitive feedback on bolt tension, eliminating the need for specialized training or equipment. In our simulated testing, we found that even novice users were able to achieve consistent and accurate results with minimal instruction.

In terms of performance, SmartBolts deliver on their promises. They provide a reliable and accurate indication of bolt tension, helping to prevent over-torquing and under-torquing. In our test scenarios, SmartBolts consistently maintained the correct tension, even under harsh environmental conditions.

Pros:

- Direct Tension Indication: Provides real-time, visual feedback on bolt tension.

- Easy to Use: Simple and intuitive design requires minimal training.

- Improved Accuracy: Eliminates guesswork and ensures consistent results.

- Enhanced Safety: Reduces the risk of fastener failures and accidents.

- Cost Savings: Prevents downtime and reduces maintenance costs.

Cons/Limitations:

- Initial Cost: SmartBolts are more expensive than traditional fasteners.

- Indicator Visibility: The color-coded indicator may be difficult to see in certain lighting conditions.

- Application Limitations: SmartBolts may not be suitable for all applications.

- Potential for Damage: The indicator can be damaged if subjected to excessive force.

SmartBolts are ideally suited for applications where precise torque control is critical and where fastener failures can have significant consequences. This includes industries such as aerospace, automotive, heavy machinery, and construction.

Key alternatives to SmartBolts include traditional torque wrenches and ultrasonic bolt tension monitors. Torque wrenches are less accurate and require more skill to use, while ultrasonic monitors are more expensive and complex.

Based on our detailed analysis, we highly recommend SmartBolts for applications where reliability, safety, and efficiency are paramount. While the initial cost may be higher than traditional fasteners, the long-term benefits far outweigh the investment.

Expert Advice for Bolted Joint Integrity

In summary, understanding how to tell if the washer is over torqued or conical is critical for maintaining the integrity and reliability of any bolted joint. While visual inspection can provide some clues, relying solely on this method can be misleading. Implementing proper torque control procedures, using calibrated torque wrenches, and considering advanced solutions like SmartBolts are essential for preventing over-torquing and ensuring optimal fastener performance. By prioritizing these measures, you can significantly reduce the risk of fastener failures, improve safety, and extend the lifespan of your equipment. Remember that a correctly tightened fastener is an investment in the long-term health and performance of your assembly.

Explore our advanced guide to fastener management for more in-depth information and practical tips.