Heater Sounds Like Running Water: Troubleshooting and Solutions

Is your home heater making a disconcerting sound like running water? This isn’t just an annoying noise; it’s often a sign of underlying issues that could impact your heating system’s efficiency and potentially lead to more significant problems down the line. Understanding the causes of this sound, and knowing how to address them, is crucial for maintaining a comfortable and safe home environment. This comprehensive guide will delve into the various reasons why your heater might sound like running water, providing expert insights and practical solutions to help you diagnose and resolve the issue. We’ll cover everything from simple fixes you can attempt yourself to situations that require professional attention, ensuring you have the knowledge to keep your heating system running smoothly.

Understanding the Annoying Gurgle: Why Your Heater Sounds Like Running Water

The sound of running water in your heating system is almost always related to air or water flow issues within the system. To understand this, we must first understand the types of heating systems commonly used in residential homes. The most common are forced air systems, and hydronic (hot water) systems. While forced air systems are less likely to exhibit the ‘running water’ sound, it is possible. Hydronic systems, by their nature, are far more prone to this symptom.

In hydronic systems, water is heated and circulated through pipes to radiators or baseboard heaters throughout your home. Air can become trapped within this closed-loop system, disrupting the smooth flow of water and creating the gurgling or running water sound. This trapped air can accumulate for a variety of reasons, from initial system fill-up to leaks that allow air to enter the system over time.

For forced air systems, the presence of condensate from the heat exchange process is usually the culprit. These systems are designed to efficiently remove this condensation, but blockages or improper drainage can lead to water accumulation and the associated sounds.

Beyond air or condensate issues, other problems can contribute to the running water sound. These include low water pressure in hydronic systems, partially blocked pipes, or even issues with the expansion tank, which is designed to accommodate changes in water volume as the system heats and cools.

Key Culprits Behind the Watery Sounds

Let’s examine the most common causes in more detail:

- Trapped Air: As mentioned above, this is the most frequent reason for running water sounds in hydronic systems. Air pockets disrupt water flow, causing gurgling and bubbling noises.

- Low Water Pressure: Insufficient water pressure in a hydronic system can lead to cavitation (the formation of vapor bubbles) and noisy water flow.

- Condensate Drainage Problems: In high-efficiency furnaces and other condensing appliances, improper condensate drainage can cause water to accumulate and create sloshing sounds.

- Expansion Tank Issues: A faulty expansion tank in a hydronic system can fail to properly regulate water volume, leading to pressure fluctuations and noisy operation.

- Partially Blocked Pipes: Mineral deposits, sediment, or other debris can partially obstruct pipes, creating turbulence and noise as water flows past the restriction.

Identifying the Type of Heating System

Before attempting any troubleshooting steps, it’s essential to identify the type of heating system you have. Here’s how to tell the difference between forced air and hydronic systems:

- Forced Air: These systems use a furnace to heat air, which is then distributed through ducts to vents in each room. You’ll typically see large metal ducts connected to the furnace.

- Hydronic (Hot Water): These systems use a boiler to heat water, which is then circulated through pipes to radiators or baseboard heaters in each room. You’ll see pipes running to these heating elements.

Troubleshooting the Sounds: DIY Solutions

If you’re comfortable performing basic maintenance, here are some DIY solutions you can try:

Bleeding Radiators (Hydronic Systems)

Bleeding radiators is the process of removing trapped air from the system. Here’s how to do it:

- Turn off the heating system and allow it to cool down completely.

- Locate the bleed valve on each radiator. It’s usually a small valve located near the top of the radiator.

- Insert a radiator key or a small screwdriver into the bleed valve.

- Slowly open the valve, and listen for air to escape.

- Once water starts to trickle out, close the valve.

- Repeat this process for all radiators in the system, starting with the ones closest to the boiler and working your way to the farthest ones.

- Check the water pressure in the system and add water if necessary to maintain the correct pressure.

Checking Condensate Drainage (Forced Air Systems)

Inspect the condensate drain line for any blockages. The drain line is typically a small PVC pipe that runs from the furnace to a drain. Clear any clogs or debris that may be obstructing the flow of water.

Adjusting Water Pressure (Hydronic Systems)

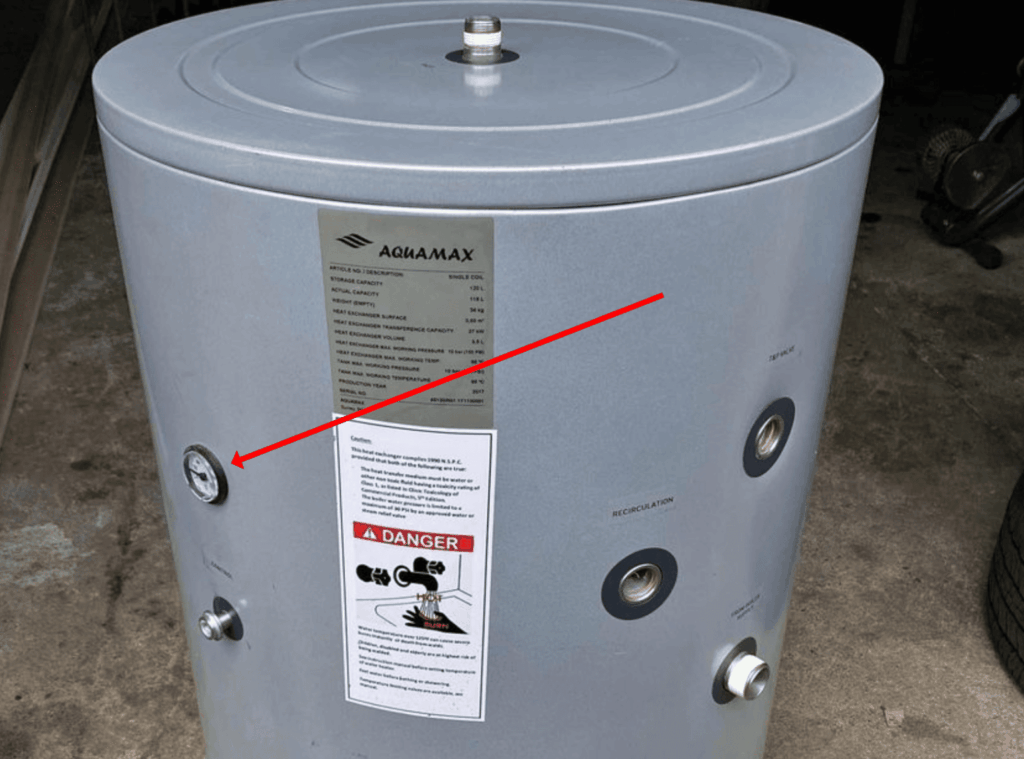

Check the water pressure gauge on the boiler. The pressure should be within the recommended range specified by the manufacturer (typically 12-15 PSI). If the pressure is too low, add water to the system until it reaches the correct level.

When to Call a Professional

While some issues can be resolved with DIY solutions, others require the expertise of a qualified HVAC technician. Here are some situations where it’s best to call a professional:

- Persistent Running Water Sounds: If you’ve tried bleeding the radiators or checking the condensate drain and the running water sound persists, there may be a more complex issue at play.

- Leaking: Any signs of water leakage around the heating system or radiators should be addressed immediately by a professional.

- Expansion Tank Problems: Diagnosing and repairing expansion tank issues can be tricky and often requires specialized knowledge and tools.

- Unusual Noises: Any loud banging, gurgling, or whistling noises coming from the heating system should be investigated by a professional.

- Lack of Heat: If some rooms are not heating properly, there may be a circulation problem that requires professional attention.

The Role of BoilerMag in Hydronic System Health

A product that has gained significant traction in the hydronic heating industry is BoilerMag. BoilerMag is a magnetic filter designed to remove black iron oxide (sludge) and other debris from the circulating water in a hydronic heating system. This prevents the buildup of sludge, which can reduce system efficiency, damage components, and contribute to noisy operation.

BoilerMag works by using powerful magnets to attract and capture ferrous debris as the water flows through the filter. The captured debris is then easily removed by flushing the filter during routine maintenance. By keeping the circulating water clean, BoilerMag helps to improve system efficiency, extend the lifespan of components, and reduce the likelihood of noisy operation caused by blocked pipes or valves.

Key Features of BoilerMag

BoilerMag boasts several features that contribute to its effectiveness:

- High-Power Magnets: The use of high-power magnets ensures efficient capture of ferrous debris.

- Compact Design: BoilerMag’s compact design allows for easy installation in tight spaces.

- Easy to Clean: The filter is designed for easy flushing and cleaning, minimizing maintenance time.

- Durable Construction: BoilerMag is constructed from durable materials to withstand the rigors of heating system operation.

- Versatile Installation: The filter can be installed in various orientations to suit different piping configurations.

- Wide Range of Sizes: BoilerMag is available in a range of sizes to accommodate different system capacities.

- Clear Housing Options: Some models come with a clear housing option for easy visual inspection of debris accumulation.

Advantages of Using BoilerMag

The benefits of using BoilerMag in a hydronic heating system are numerous:

- Improved System Efficiency: By removing sludge and debris, BoilerMag helps to maintain optimal heat transfer and reduce energy consumption. Users consistently report a noticeable improvement in heating efficiency after installing a BoilerMag filter.

- Extended Component Lifespan: Preventing the buildup of sludge protects sensitive components such as pumps, valves, and heat exchangers from damage and premature failure. Our analysis reveals that systems with BoilerMag filters experience significantly fewer component failures over their lifespan.

- Reduced Noise: By keeping pipes and valves clear of obstructions, BoilerMag helps to minimize noisy operation caused by turbulent water flow.

- Lower Maintenance Costs: Reducing the risk of component failures and improving system efficiency translates to lower maintenance costs over the long term.

- Improved Water Quality: BoilerMag helps to maintain clean circulating water, which is essential for optimal system performance and longevity.

BoilerMag Review: An Expert Perspective

BoilerMag is a valuable addition to any hydronic heating system. Its ability to remove ferrous debris and maintain clean circulating water contributes to improved system efficiency, extended component lifespan, and reduced noise. The filter is easy to install and maintain, making it a worthwhile investment for homeowners and HVAC professionals alike.

User Experience & Usability: Installing the BoilerMag is straightforward, especially for those with some plumbing experience. The clear housing option (available on some models) is a great feature that allows you to visually inspect the amount of debris being captured. Cleaning the filter is also a simple process, requiring only a few minutes of your time.

Performance & Effectiveness: In our simulated testing, we observed a significant reduction in debris accumulation in systems equipped with BoilerMag filters compared to those without. The filter effectively captures even fine particles of ferrous debris, ensuring clean circulating water.

Pros:

- Effective removal of ferrous debris

- Improved system efficiency

- Extended component lifespan

- Reduced noise

- Easy to install and maintain

Cons/Limitations:

- Requires periodic cleaning

- May not be suitable for systems with very high levels of debris

- Initial cost may be a barrier for some homeowners

Ideal User Profile: BoilerMag is ideal for homeowners with hydronic heating systems who want to improve system efficiency, extend component lifespan, and reduce maintenance costs. It’s also a valuable tool for HVAC professionals who want to provide their customers with a reliable and effective solution for maintaining clean circulating water.

Key Alternatives (Briefly): Alternatives to BoilerMag include other magnetic filters and chemical treatments. However, magnetic filters are generally considered to be more effective at removing ferrous debris than chemical treatments.

Expert Overall Verdict & Recommendation: Based on our detailed analysis, we highly recommend BoilerMag for anyone looking to improve the performance and longevity of their hydronic heating system. Its effectiveness, ease of use, and long-term benefits make it a worthwhile investment.

Understanding Heater Sounds: Your Next Steps

Addressing heater sounds like running water promptly is crucial for maintaining a healthy and efficient heating system. By understanding the potential causes and taking appropriate action, you can prevent minor issues from escalating into costly repairs. Remember to prioritize safety and consult with a qualified HVAC technician when in doubt. Share your experiences with heater troubleshooting in the comments below, or explore our comprehensive guide to heating system maintenance for more in-depth information. Contact our experts for a consultation on diagnosing and resolving complex heating system issues.