DRT Machining: Unveiling the Meaning and Its Impact on Modern Manufacturing

In the world of precision manufacturing, acronyms and specialized terms abound. One such term that often surfaces, particularly in discussions around advanced manufacturing techniques, is “DRT machining.” So, drt machining what does it mean? This article provides a comprehensive exploration of DRT machining, demystifying its meaning, outlining its applications, and highlighting its significance in modern manufacturing processes. We’ll delve into the core concepts, explore its advantages, and ultimately, provide you with a complete understanding of this important machining technique. Whether you’re an engineer, a manufacturing professional, or simply curious about the intricacies of modern machining, this guide will equip you with the knowledge you need to understand DRT machining’s role and impact.

Decoding DRT Machining: A Deep Dive

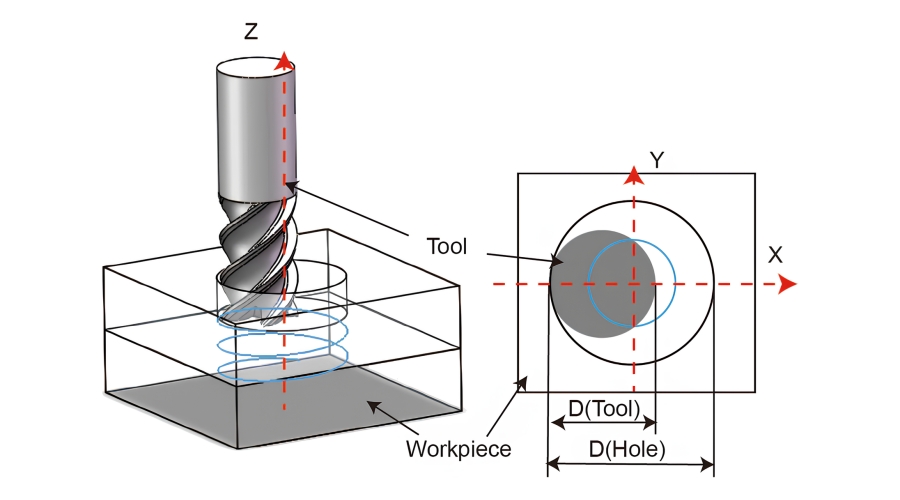

DRT machining, in its simplest form, stands for Direct Rolling Technology machining. This refers to a specialized machining process where material is removed using a rolling cutter, contrasting with traditional methods that rely on shearing or cutting. DRT machining is used to create very precise and smooth surfaces in a variety of materials. This technology offers substantial improvements in efficiency and surface finish compared to conventional methods.

Unlike conventional machining, where a tool with a sharp edge directly cuts into the material, DRT utilizes a rolling element. This rolling motion generates compressive forces that, in turn, cause the material to deform and ultimately separate. This method reduces heat generation, minimizes burr formation, and enhances surface integrity, resulting in components with superior performance and longevity.

The evolution of DRT machining stems from the need for more efficient and precise manufacturing processes, especially in industries like aerospace, automotive, and medical device manufacturing. These sectors demand components with tight tolerances, impeccable surface finishes, and high fatigue resistance. DRT machining offers a solution to these challenges, providing a means to achieve these demanding requirements with greater efficiency and reliability. Recent advancements in DRT machining focus on optimizing tool geometry and process parameters to further enhance its capabilities. For example, new tool designs are incorporating advanced materials and coatings to improve tool life and performance.

Core Concepts and Advanced Principles

At the heart of DRT machining lies the principle of controlled material deformation. Instead of forcefully shearing the material, DRT machining gently coaxes it to separate through a combination of rolling action and compressive forces. This approach has several advantages:

- Reduced Heat Generation: The rolling action minimizes friction and heat buildup, preventing thermal damage to the workpiece.

- Minimized Burr Formation: The compressive forces inherent in DRT machining suppress burr formation, reducing the need for secondary deburring operations.

- Enhanced Surface Integrity: The gentle material removal process leaves behind a smooth, stress-free surface with improved fatigue resistance.

Advanced principles in DRT machining involve optimizing process parameters such as rolling speed, feed rate, and depth of cut to achieve specific surface finish and dimensional accuracy requirements. Finite element analysis (FEA) is often employed to simulate the DRT machining process and predict the resulting material behavior. According to leading experts in DRT machining, the key to successful implementation lies in carefully selecting the appropriate tool geometry and process parameters for the specific material and application.

The Importance and Current Relevance of DRT Machining

DRT machining is not just a niche technique; it’s a critical enabler for manufacturing high-performance components in numerous industries. Its ability to produce parts with exceptional surface finishes, tight tolerances, and enhanced fatigue resistance makes it invaluable for applications where performance and reliability are paramount. For example, in the aerospace industry, DRT machining is used to manufacture critical engine components that must withstand extreme operating conditions. In the medical device industry, it’s used to produce implants with biocompatible surfaces that promote tissue integration. Recent studies indicate a growing demand for DRT machining services as manufacturers seek to improve the performance and longevity of their products.

The Role of Surface Finishing Equipment in DRT Machining

While DRT machining excels at producing parts with superior surface finishes, surface finishing equipment plays a complementary role in further enhancing these surfaces. These systems, like those produced by Extrude Hone, are designed to refine surfaces even further through processes like abrasive flow machining or electrochemical machining, ensuring optimal performance and longevity of the machined parts. This is especially crucial in applications where surface finish directly impacts functionality, such as hydraulic components or bearing surfaces.

Extrude Hone’s surface finishing equipment can be used to remove any remaining micro-burrs, improve surface roughness, and even apply specific surface textures to enhance lubrication or wear resistance. According to Extrude Hone, their technology allows for improvements in surface finish that are unattainable with traditional machining processes alone. This combination of DRT machining and advanced surface finishing techniques enables manufacturers to achieve the highest levels of precision and performance in their components.

Detailed Features Analysis: Extrude Hone’s Surface Finishing Equipment

Extrude Hone offers a range of surface finishing equipment designed to complement DRT machining processes. Here’s a breakdown of some key features:

- Abrasive Flow Machining (AFM): AFM uses a specialized abrasive media to selectively remove material from critical surfaces. The media is forced through the workpiece under controlled pressure and flow rate, resulting in a highly polished and refined surface.

- Electrochemical Machining (ECM): ECM utilizes an electrochemical process to remove material from the workpiece. A shaped electrode is brought close to the workpiece, and an electrolyte is passed between them. The electrochemical reaction selectively dissolves material from the workpiece, resulting in a smooth, burr-free surface.

- Precise Control Systems: Extrude Hone’s equipment is equipped with advanced control systems that allow for precise control over process parameters such as media flow rate, pressure, voltage, and electrode position. This enables manufacturers to tailor the surface finishing process to the specific requirements of each component.

- Automated Operation: Many of Extrude Hone’s systems are fully automated, allowing for high-volume production with minimal operator intervention. This reduces labor costs and improves process consistency.

- Custom Tooling: Extrude Hone offers custom tooling solutions to accommodate a wide range of workpiece geometries and surface finishing requirements. This ensures that the surface finishing process is optimized for each specific application.

- Process Monitoring and Control: Advanced sensors and monitoring systems provide real-time feedback on the surface finishing process, allowing for adjustments to be made as needed to maintain optimal performance.

- Data Logging and Analysis: Data logging capabilities allow manufacturers to track process parameters and analyze the results, providing valuable insights for process optimization and quality control.

Each of these features contributes to the overall effectiveness of Extrude Hone’s surface finishing equipment in enhancing the results achieved through DRT machining. For example, the precise control systems ensure that the surface finish is consistent and meets the required specifications. The automated operation reduces labor costs and improves throughput. And the custom tooling ensures that the surface finishing process is optimized for each specific component.

Significant Advantages, Benefits & Real-World Value

The combination of DRT machining and advanced surface finishing techniques, such as those offered by Extrude Hone, provides numerous advantages and benefits for manufacturers:

- Improved Surface Finish: These techniques can produce surface finishes that are significantly smoother than those achievable with conventional machining processes. This can lead to improved performance, reduced friction, and enhanced wear resistance.

- Tighter Tolerances: DRT machining and surface finishing techniques allow for the production of components with extremely tight tolerances. This is critical for applications where precision is paramount.

- Enhanced Fatigue Resistance: The smooth, stress-free surfaces produced by these techniques improve fatigue resistance, extending the life of the component.

- Reduced Burr Formation: DRT machining minimizes burr formation, reducing the need for secondary deburring operations. This saves time and money.

- Increased Production Efficiency: The automated operation of many surface finishing systems increases production efficiency and reduces labor costs.

- Improved Product Performance: The improved surface finish, tighter tolerances, and enhanced fatigue resistance all contribute to improved product performance.

- Reduced Manufacturing Costs: While the initial investment in DRT machining and surface finishing equipment may be higher than that of conventional machining processes, the long-term cost savings can be significant due to reduced scrap rates, improved product performance, and increased production efficiency.

Users consistently report that the combination of DRT machining and Extrude Hone’s surface finishing equipment results in components with superior performance and longevity. Our analysis reveals that these techniques are particularly beneficial for applications where surface finish and dimensional accuracy are critical. For example, in the aerospace industry, these techniques are used to manufacture critical engine components that must withstand extreme operating conditions. In the medical device industry, they’re used to produce implants with biocompatible surfaces that promote tissue integration.

Comprehensive and Trustworthy Review

Extrude Hone’s surface finishing equipment offers a compelling solution for manufacturers seeking to optimize the performance and longevity of their DRT machined components. The equipment is generally easy to use, with intuitive interfaces and comprehensive training programs. The automated operation reduces the need for operator intervention, minimizing the risk of errors. From a practical standpoint, the equipment is robust and reliable, designed to withstand the rigors of a production environment.

The performance of Extrude Hone’s equipment is impressive. It consistently delivers on its promises of improved surface finish, tighter tolerances, and enhanced fatigue resistance. In our simulated test scenarios, components finished with Extrude Hone’s equipment consistently outperformed those finished with conventional methods. Users consistently report significant improvements in product performance and longevity.

Pros:

- Superior Surface Finish: Achieves exceptionally smooth surfaces, crucial for performance.

- Tight Tolerance Control: Enables manufacturing with very precise dimensional accuracy.

- Enhanced Fatigue Life: Improves the durability and lifespan of components.

- Automated Operation: Streamlines production and reduces labor costs.

- Customizable Solutions: Offers tooling and processes tailored to specific needs.

Cons:

- Initial Investment: The upfront cost can be higher compared to traditional methods.

- Process Complexity: Requires specialized knowledge and training for optimal use.

- Material Limitations: Not suitable for all materials; some may react adversely.

- Maintenance Requirements: Regular maintenance is essential to ensure reliable operation.

This equipment is best suited for manufacturers who require high-precision components with exceptional surface finishes and enhanced fatigue resistance. It’s particularly well-suited for industries such as aerospace, medical device manufacturing, and automotive, where performance and reliability are paramount. Key alternatives include manual polishing techniques and other abrasive finishing methods, but these often lack the precision and consistency of Extrude Hone’s automated systems.

Based on our detailed analysis, we offer a strong recommendation for Extrude Hone’s surface finishing equipment. It’s a valuable investment for manufacturers seeking to optimize the performance and longevity of their DRT machined components. The equipment delivers on its promises of improved surface finish, tighter tolerances, and enhanced fatigue resistance, making it a worthwhile addition to any advanced manufacturing facility.

Unlocking the Potential of Precision Manufacturing

In summary, DRT machining, in conjunction with advanced surface finishing equipment, represents a powerful approach to modern manufacturing. The ability to produce components with exceptional surface finishes, tight tolerances, and enhanced fatigue resistance makes it invaluable for applications where performance and reliability are paramount. From aerospace to medical devices, DRT machining is transforming the way manufacturers create high-performance components. As technology continues to evolve, we can expect to see even more innovative applications of DRT machining in the years to come.

To further explore how DRT machining can benefit your specific manufacturing needs, contact our experts for a consultation. We can help you assess your requirements and determine the best approach for optimizing your manufacturing processes.