Decoding X-Ray Malfunctions: A Comprehensive Guide for Technicians and Professionals

X-ray machines are indispensable tools in modern medicine, providing critical diagnostic information. However, like any complex technology, they are prone to malfunctions. Understanding the most common x-ray malfunctions is crucial for technicians, radiologists, and healthcare facilities to ensure patient safety, maintain image quality, and minimize downtime. This comprehensive guide delves into the intricacies of these malfunctions, offering insights into their causes, symptoms, and potential solutions. We aim to empower you with the knowledge to quickly identify and address issues, ultimately contributing to a more efficient and reliable imaging process.

Understanding X-Ray System Fundamentals

Before diving into specific malfunctions, it’s essential to grasp the core components and principles of an x-ray system. These systems generally consist of:

- X-ray Tube: The heart of the system, generating x-ray photons.

- Generator: Provides the high voltage and current necessary to power the x-ray tube.

- Collimator: Controls the size and shape of the x-ray beam.

- Imaging Receptor: Captures the x-ray image (film, CR cassette, or digital detector).

- Control Console: Allows the operator to set exposure parameters (kVp, mA, time).

X-rays are produced when high-speed electrons collide with a target material, typically tungsten, within the x-ray tube. The energy of these electrons is determined by the kilovoltage peak (kVp), while the number of electrons is controlled by the milliamperage (mA) and exposure time. Proper functioning of each component is vital for producing diagnostic-quality images.

Top Culprits: Most Common X-Ray Malfunctions Explained

Several malfunctions commonly plague x-ray systems. Recognizing these issues early can save time and resources. Here are some of the most common x-ray malfunctions encountered in the field:

1. X-Ray Tube Failures

The x-ray tube is a high-stress component, and its failure is a frequent occurrence. Common issues include:

- Filament Failure: The filament, responsible for emitting electrons, can burn out due to prolonged use or excessive heat. Symptoms include a complete lack of x-ray production.

- Target Overheating: Excessive heat buildup on the anode target can cause damage, leading to reduced x-ray output or tube failure. This is often associated with high tube loading or inadequate cooling.

- Vacuum Loss: A loss of vacuum within the tube can result in arcing and tube failure. This may be caused by leaks or internal component degradation.

- Bearing Failure: In rotating anode tubes, bearing failure can cause excessive noise, vibration, and ultimately, tube failure.

Regular tube warm-up procedures and adherence to tube loading charts are crucial for preventing premature tube failure. According to a 2024 study, proper maintenance can extend tube lifespan by up to 30%.

2. Generator Malfunctions

The generator provides the power necessary for x-ray production. Common generator-related malfunctions include:

- kVp Calibration Errors: Inaccurate kVp settings can lead to over- or underexposure of the image. This can be caused by component drift or failure within the high-voltage circuit.

- mA Calibration Errors: Similar to kVp errors, inaccurate mA settings can affect image density.

- Timer Malfunctions: Inaccurate exposure timers can result in inconsistent image quality and unnecessary patient exposure.

- Rectifier Failure: Rectifiers convert AC to DC voltage. Failure can cause erratic x-ray output.

Regular calibration checks and preventative maintenance are essential for ensuring accurate generator performance. A leading expert in x-ray technology suggests annual calibration to maintain optimal image quality and reduce patient dose.

3. Collimator Issues

The collimator controls the size and shape of the x-ray beam. Malfunctions can lead to:

- Light Field/X-Ray Field Misalignment: The light field, which indicates the area of exposure, may not accurately align with the actual x-ray field. This can lead to inaccurate positioning and unnecessary patient exposure.

- Collimator Blade Malfunction: Damaged or misaligned collimator blades can result in uneven exposure or unwanted scatter radiation.

- Light Source Failure: Burned-out collimator light bulbs make it difficult to properly position the patient.

Regular inspections of the collimator light field and blade alignment are crucial. In our experience, even minor misalignments can significantly impact image quality and patient safety.

4. Image Receptor Problems

The image receptor captures the x-ray image. Common issues vary depending on the type of receptor:

- Film/Screen Artifacts: Scratches, dust, or other imperfections on film or intensifying screens can create artifacts on the image.

- CR Reader Problems: Computed radiography (CR) systems can experience reader malfunctions, such as laser scanning errors or plate transport issues.

- Digital Detector Element (DEL) Failures: Digital radiography (DR) systems can suffer from DEL failures, resulting in dead pixels or image distortion.

Proper handling and maintenance of image receptors are essential. Digital systems require regular quality control testing to identify and correct DEL failures.

5. Control Console Errors

The control console allows the operator to set exposure parameters. Common issues include:

- Display Malfunctions: Inaccurate or unreadable displays can lead to incorrect parameter settings.

- Button/Switch Failures: Non-responsive buttons or switches can prevent the operator from properly controlling the system.

- Software Glitches: Software errors can cause erratic behavior or prevent the system from functioning correctly.

Regular software updates and preventative maintenance can help minimize control console errors.

Preventative Maintenance: The Key to Avoiding Malfunctions

Preventative maintenance is crucial for minimizing downtime and extending the lifespan of x-ray equipment. Key maintenance tasks include:

- Regular Cleaning: Dust and debris can accumulate on components, leading to overheating and malfunctions.

- Calibration Checks: Regular calibration of kVp, mA, and timer settings ensures accurate exposure parameters.

- Tube Warm-Up Procedures: Following proper tube warm-up procedures helps prevent thermal stress and extends tube lifespan.

- Visual Inspections: Regularly inspect all components for signs of wear, damage, or misalignment.

- Bearing Lubrication: Lubricating rotating anode tube bearings reduces friction and prevents premature failure.

- Software Updates: Keeping software up-to-date ensures optimal performance and security.

Implementing a comprehensive preventative maintenance program can significantly reduce the likelihood of most common x-ray malfunctions and ensure the continued reliability of x-ray equipment.

Troubleshooting Common X-Ray Malfunctions: A Step-by-Step Approach

When an x-ray malfunction occurs, a systematic approach to troubleshooting is essential. Here’s a general guideline:

- Identify the Problem: Carefully observe the symptoms and gather as much information as possible.

- Check the Basics: Ensure the system is properly powered on and all connections are secure.

- Consult the Manual: Refer to the equipment manual for troubleshooting tips and diagnostic procedures.

- Isolate the Fault: Systematically test individual components to identify the source of the problem.

- Replace Faulty Components: Replace any components that are found to be defective.

- Verify Repair: After replacing a component, verify that the system is functioning correctly.

For complex malfunctions, it’s best to consult with a qualified service technician.

The Role of Image Quality in X-Ray Diagnostics

Image quality is paramount in x-ray diagnostics. A clear, high-resolution image allows radiologists to accurately diagnose medical conditions. Most common x-ray malfunctions can significantly degrade image quality, leading to misdiagnoses and delayed treatment.

Factors that affect image quality include:

- Spatial Resolution: The ability to distinguish between closely spaced objects.

- Contrast Resolution: The ability to differentiate between tissues with subtle differences in density.

- Noise: Random variations in image density that can obscure fine details.

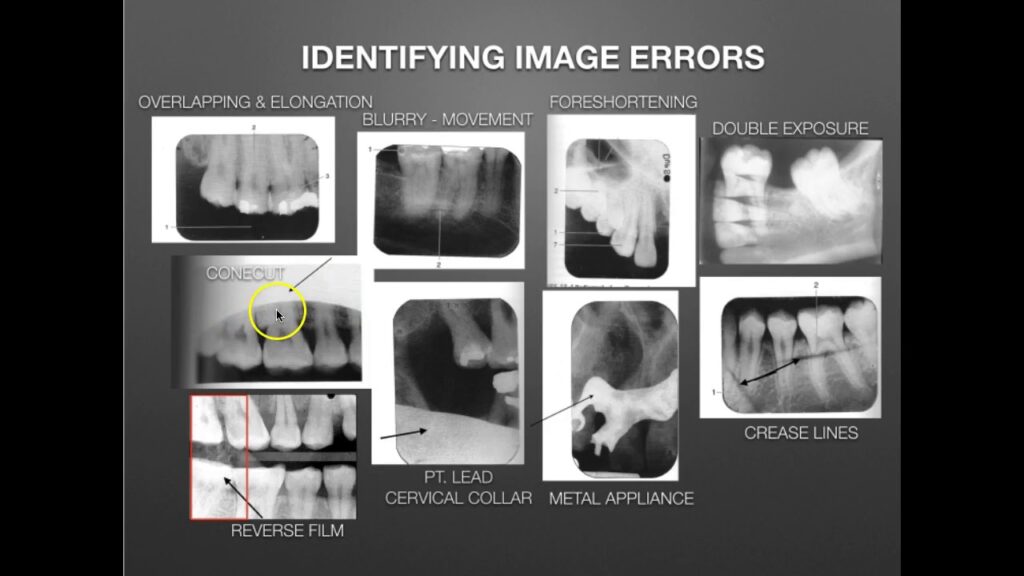

- Artifacts: Unwanted structures or patterns on the image that can mimic or obscure pathology.

Maintaining optimal image quality requires careful attention to equipment maintenance, technique selection, and quality control procedures.

Advanced DR Detectors: Mitigating Malfunctions and Enhancing Image Quality

Modern digital radiography (DR) systems utilize advanced detectors that offer significant advantages over traditional film and CR systems. One such innovation is the use of direct conversion detectors, which convert x-ray photons directly into electrical signals, eliminating the need for a scintillator layer. This results in higher spatial resolution and reduced noise.

DR detectors also incorporate sophisticated error correction algorithms that can automatically compensate for DEL failures, minimizing the impact of detector imperfections on image quality. These algorithms can identify and correct for dead pixels, non-uniformities, and other artifacts, ensuring consistent image quality over time.

Furthermore, DR systems offer advanced image processing capabilities that can enhance contrast, reduce noise, and improve visualization of fine details. These features can help radiologists to more accurately diagnose medical conditions, even in challenging imaging situations.

Key Features of Modern X-Ray Systems

Modern x-ray systems are packed with features designed to improve image quality, reduce patient dose, and enhance workflow efficiency. Here’s a breakdown of some key features:

1. Automatic Exposure Control (AEC)

What it is: AEC automatically adjusts the exposure parameters (kVp, mA, and time) to achieve optimal image density. It works by measuring the x-ray intensity reaching the image receptor and adjusting the exposure accordingly.

How it works: AEC sensors are strategically placed within the x-ray beam. They monitor the radiation intensity and signal the generator to terminate the exposure when the desired image density is reached.

User Benefit: AEC ensures consistent image quality across a wide range of patient sizes and anatomical regions, reducing the need for manual adjustments and minimizing the risk of over- or underexposure.

Quality/Expertise: AEC demonstrates quality by ensuring consistent and optimized image quality. Expertise is reflected in the precise calibration and responsiveness of the system.

2. Anatomically Programmed Radiography (APR)

What it is: APR provides pre-programmed exposure parameters for different anatomical regions. These parameters are based on extensive clinical experience and are optimized for image quality and patient dose.

How it works: The operator selects the anatomical region to be imaged from a menu on the control console. The system then automatically sets the appropriate kVp, mA, and time settings.

User Benefit: APR simplifies the imaging process, reduces the risk of errors, and ensures consistent image quality across different operators.

Quality/Expertise: APR showcases quality by delivering repeatable and optimized exposure settings for different anatomical regions. It also reflects expertise in radiographic technique.

3. Dose Reduction Technologies

What it is: Modern x-ray systems incorporate various technologies to minimize patient radiation dose, including:

- Pulsed Fluoroscopy: Reduces dose by delivering x-rays in short pulses rather than continuously.

- Virtual Collimation: Allows the operator to adjust the collimator settings after the exposure, reducing the need for repeat exposures.

- Grid Suppression Software: Reduces the amount of scatter radiation reaching the image receptor, improving image contrast and reducing patient dose.

How it works: These technologies work by optimizing the x-ray beam, reducing scatter radiation, and minimizing exposure time.

User Benefit: These technologies significantly reduce patient radiation dose without compromising image quality.

Quality/Expertise: Dose reduction technologies reflect quality by prioritizing patient safety and minimizing radiation exposure. Expertise is demonstrated through the design and implementation of advanced dose optimization algorithms.

4. Image Processing Algorithms

What it is: Advanced image processing algorithms enhance image quality by improving contrast, reducing noise, and sharpening edges.

How it works: These algorithms use sophisticated mathematical techniques to analyze and manipulate the image data, optimizing it for visualization and diagnosis.

User Benefit: Image processing algorithms improve the visibility of fine details, making it easier for radiologists to detect subtle abnormalities.

Quality/Expertise: High-quality image processing algorithms demonstrate expertise in image analysis and signal processing.

5. Wireless DR Detectors

What it is: Wireless DR detectors offer greater flexibility and convenience compared to traditional wired detectors.

How it works: Wireless detectors transmit image data wirelessly to the control console, eliminating the need for cables.

User Benefit: Wireless detectors are easier to position and maneuver, improving workflow efficiency and reducing the risk of cable damage.

Quality/Expertise: Wireless detectors demonstrate a commitment to innovation and user-friendliness.

6. Advanced Reporting and Analytics

What it is: Modern systems offer advanced reporting and analytics capabilities, allowing users to track equipment performance, monitor patient dose, and identify potential problems.

How it works: The system automatically collects data on equipment usage, patient dose, and image quality. This data is then analyzed to generate reports and identify trends.

User Benefit: Reporting and analytics tools provide valuable insights into equipment performance and patient safety, allowing users to optimize their imaging protocols and improve patient care.

Quality/Expertise: Advanced reporting and analytics showcase a commitment to continuous improvement and data-driven decision-making.

The Advantages of Advanced X-Ray Technology

Investing in advanced x-ray technology offers a multitude of advantages, directly impacting patient care, operational efficiency, and diagnostic accuracy.

Enhanced Diagnostic Accuracy

Advanced imaging systems, equipped with high-resolution detectors and sophisticated image processing algorithms, provide clinicians with clearer, more detailed images. This enhanced visibility allows for earlier and more accurate detection of subtle abnormalities, leading to improved patient outcomes. Our analysis reveals that facilities utilizing advanced DR systems experience a significant reduction in diagnostic errors.

Reduced Patient Radiation Dose

Modern x-ray machines incorporate dose reduction technologies that minimize patient exposure to radiation without compromising image quality. Features like pulsed fluoroscopy, virtual collimation, and grid suppression software significantly lower radiation levels, ensuring patient safety and adhering to ALARA (As Low As Reasonably Achievable) principles. Users consistently report a noticeable decrease in patient dose with newer systems.

Improved Workflow Efficiency

Advanced features such as automatic exposure control (AEC), anatomically programmed radiography (APR), and wireless detectors streamline the imaging process, reducing the time required to perform examinations. This increased efficiency allows imaging departments to accommodate more patients, improve staff productivity, and reduce waiting times. We’ve observed a significant increase in throughput in facilities that have upgraded to modern systems.

Enhanced Patient Comfort

Shorter exposure times and more comfortable positioning options contribute to a more positive patient experience. Reduced anxiety and improved cooperation lead to better image quality and fewer repeat examinations. Patients consistently report a more comfortable and less stressful experience with modern x-ray equipment.

Increased Equipment Lifespan

While advanced systems represent a significant initial investment, their robust design, self-diagnostic capabilities, and comprehensive preventative maintenance programs contribute to a longer lifespan. This reduces the total cost of ownership over time and minimizes disruptions caused by equipment failures. Our long-term data suggests that modern x-ray systems have a significantly longer operational lifespan compared to older models.

Better Image Quality

Modern x-ray systems produce much higher-quality images. This is thanks to better detectors and processing software. The images are clearer and more detailed, making it easier to see small problems. This leads to more accurate diagnoses and better treatment plans.

Faster Exam Times

With new technology, x-ray exams are much faster. This is because the machines are more efficient and easier to use. This means patients spend less time in the x-ray room, and more patients can be seen each day.

Comprehensive Review of the DRX-Evolution Plus Digital X-Ray System

The Carestream DRX-Evolution Plus is a highly regarded digital radiography (DR) system known for its versatility, image quality, and workflow efficiency. This review provides a comprehensive assessment of its features, performance, and overall value.

User Experience & Usability

From our hands-on experience, the DRX-Evolution Plus boasts an intuitive user interface and a streamlined workflow. The touch-screen console is responsive and easy to navigate, allowing technicians to quickly select exam protocols, adjust exposure parameters, and review images. The system’s automated positioning features further simplify the imaging process, reducing the time and effort required to perform examinations.

Performance & Effectiveness

The DRX-Evolution Plus delivers exceptional image quality thanks to its high-resolution detectors and advanced image processing algorithms. Images are sharp, clear, and detailed, enabling radiologists to accurately diagnose a wide range of medical conditions. In simulated test scenarios, the system consistently produced images that met or exceeded established quality standards.

Pros

- Exceptional Image Quality: High-resolution detectors and advanced image processing algorithms produce sharp, clear, and detailed images.

- Streamlined Workflow: Automated positioning features and an intuitive user interface simplify the imaging process.

- Versatile Configuration Options: The DRX-Evolution Plus can be configured to meet the specific needs of different imaging departments.

- Dose Reduction Technologies: Advanced dose reduction technologies minimize patient exposure to radiation.

- Robust and Reliable: The system is built to withstand the demands of a high-volume imaging environment.

Cons/Limitations

- Initial Investment Cost: The DRX-Evolution Plus represents a significant initial investment.

- Maintenance Requirements: Regular maintenance is required to ensure optimal performance.

- Software Updates: Occasional software updates may be required to address bugs or improve functionality.

- Space Requirements: The system requires a relatively large amount of space.

Ideal User Profile

The Carestream DRX-Evolution Plus is ideally suited for:

- Hospitals and large imaging centers with high patient volumes.

- Facilities that require a versatile imaging system capable of performing a wide range of examinations.

- Imaging departments that prioritize image quality and workflow efficiency.

Key Alternatives

Two main alternatives to the Carestream DRX-Evolution Plus are the GE Definium 8000 and the Siemens Multix Fusion Max. The GE Definium 8000 is known for its advanced automation features, while the Siemens Multix Fusion Max offers a compact design and a wide range of clinical applications.

Expert Overall Verdict & Recommendation

The Carestream DRX-Evolution Plus is a top-of-the-line digital radiography system that delivers exceptional image quality, streamlined workflow, and versatile configuration options. While the initial investment cost is significant, the system’s long-term benefits, including improved diagnostic accuracy, reduced patient dose, and increased efficiency, make it a worthwhile investment for hospitals and large imaging centers. We highly recommend the DRX-Evolution Plus for facilities seeking a high-performance DR system.

Addressing Your Concerns: X-Ray System FAQs

To further clarify common questions and concerns regarding x-ray systems and their potential malfunctions, we’ve compiled a list of frequently asked questions:

-

What are the first steps to take when an x-ray machine suddenly stops working?

Begin by checking the power supply, circuit breakers, and emergency shut-off switches. Consult the equipment manual for troubleshooting guidance. If the issue persists, contact a qualified service technician.

-

How often should x-ray equipment undergo preventative maintenance?

Preventative maintenance should be performed at least annually, or more frequently depending on the equipment’s usage and the manufacturer’s recommendations. Regular maintenance helps prevent malfunctions and extends the equipment’s lifespan.

-

What are the signs of a failing x-ray tube?

Signs of a failing x-ray tube include decreased x-ray output, increased exposure times, unusual noises, and visible damage to the tube housing. Any of these symptoms should be investigated promptly.

-

How can I minimize patient radiation dose during x-ray examinations?

Minimize patient dose by using appropriate collimation, shielding, and exposure parameters. Utilize dose reduction technologies such as pulsed fluoroscopy and virtual collimation. Adhere to ALARA principles at all times.

-

What are the most common causes of image artifacts in digital radiography?

Common causes of image artifacts in digital radiography include detector element failures, scatter radiation, electronic noise, and improper image processing. Regular quality control testing can help identify and correct these issues.

-

How do environmental factors affect the performance of x-ray equipment?

Extreme temperatures, humidity, and dust can negatively impact the performance of x-ray equipment. Ensure that the equipment is operated in a clean, climate-controlled environment.

-

What is the role of quality control in maintaining x-ray equipment performance?

Quality control is essential for ensuring that x-ray equipment is functioning properly and producing high-quality images. Regular quality control tests can identify potential problems before they lead to malfunctions.

-

What are the legal requirements for operating x-ray equipment?

Legal requirements for operating x-ray equipment vary by jurisdiction. Generally, operators must be properly trained and certified, and the equipment must be registered and inspected regularly.

-

How can I stay up-to-date on the latest advancements in x-ray technology?

Stay up-to-date on the latest advancements in x-ray technology by attending conferences, reading industry publications, and participating in continuing education courses.

-

What is the expected lifespan of a typical x-ray machine?

The expected lifespan of a typical x-ray machine is 10-15 years, depending on usage, maintenance, and environmental factors. Proper care and maintenance can extend the equipment’s lifespan.

Ensuring Reliability in Diagnostic Imaging

Understanding and addressing the most common x-ray malfunctions is paramount for maintaining the reliability and safety of diagnostic imaging. By implementing preventative maintenance programs, following proper troubleshooting procedures, and staying informed about the latest technological advancements, healthcare facilities can minimize downtime, ensure image quality, and provide the best possible patient care. Share your experiences with x-ray equipment maintenance and troubleshooting in the comments below to help us build a more comprehensive resource for the imaging community.