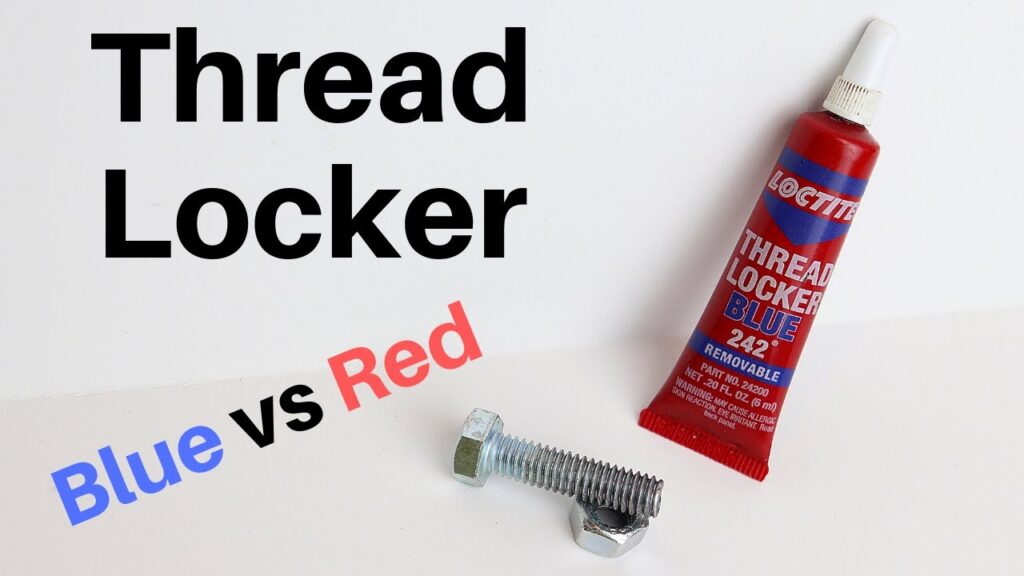

Red vs. Blue Loctite: Choosing the Right Threadlocker for Your Needs

When it comes to securing threaded fasteners, Loctite is a name synonymous with reliability. But standing in the hardware store aisle, staring at the red and blue bottles, many DIYers and even seasoned mechanics find themselves asking: red vs. blue Loctite – which one should I use? This comprehensive guide will break down the differences between these two popular threadlockers, helping you make the right choice for your project and ensuring a secure, long-lasting hold.

We’ll explore the strengths and weaknesses of each type, delve into their applications, and provide practical advice based on years of experience using these products in various automotive, industrial, and home repair scenarios. By the end of this article, you’ll have a clear understanding of when to choose red Loctite, when blue Loctite is the better option, and how to apply them correctly for optimal results.

Understanding Threadlockers: The Basics

Threadlockers are adhesives applied to the threads of fasteners, such as bolts and screws, to prevent loosening due to vibration, temperature changes, and other factors. They fill the microscopic gaps between the threads, creating a strong bond that resists movement. Loctite, a brand of Henkel, is the most widely recognized and trusted name in threadlocking technology. They come in different colors, each representing a different strength and purpose.

The core function of any threadlocker is to prevent self-loosening. This is especially critical in applications where vibration is present, like in engines, machinery, and vehicles. However, they also serve to seal the threads against corrosion and leakage, further extending the lifespan of the assembly. Choosing the right threadlocker is paramount for safety and reliability.

Red Loctite: The Permanent Solution

Red Loctite (typically Loctite 271 or 272) is a high-strength threadlocker designed for permanent applications. It creates a bond that is so strong that disassembly usually requires heat and specialized tools. It’s the go-to choice when you absolutely, positively do not want the fastener to come loose.

Specifically, Red Loctite is an anaerobic adhesive. This means it cures (hardens) in the absence of air, specifically when confined between close-fitting metal surfaces. This is why it works so well inside the threads of a nut and bolt. Once cured, it forms a tough, solvent-resistant bond that can withstand high temperatures and harsh chemicals.

When to Use Red Loctite

- Permanent Assemblies: Use red Loctite when you don’t anticipate needing to disassemble the joint in the future. Examples include securing studs in engine blocks, permanently mounting gears on shafts, or assembling components in heavy machinery.

- High-Stress Environments: Red Loctite is ideal for applications subjected to extreme vibration, shock, or chemical exposure.

- Large Fasteners: It’s particularly effective on larger bolts and studs (typically 3/8″ diameter and larger) where the increased surface area allows for a stronger bond.

The Drawbacks of Red Loctite

The primary drawback of red Loctite is the difficulty of disassembly. Attempting to remove a fastener secured with red Loctite without applying heat can result in damage to the fastener, the surrounding components, or both. It requires patience and the correct tools.

- Difficult Disassembly: Requires significant heat (typically above 500°F) and specialized tools like impact wrenches or slide hammers.

- Potential for Damage: Improper removal can strip threads or break fasteners.

- Not Suitable for Adjustments: If you need to make adjustments or perform maintenance that requires disassembly, red Loctite is not the right choice.

Blue Loctite: The Removable Option

Blue Loctite (commonly Loctite 242 or 243) is a medium-strength threadlocker designed for applications where disassembly may be required. It provides a secure hold but allows for removal with standard hand tools. It’s a versatile option suitable for a wide range of applications.

Like red Loctite, blue Loctite is also an anaerobic adhesive. However, it has a lower bond strength, making it easier to break the bond when needed. It’s the go-to choice for securing fasteners that may need to be removed for maintenance, repairs, or adjustments.

When to Use Blue Loctite

- Serviceable Assemblies: Use blue Loctite when you anticipate needing to disassemble the joint for maintenance or repairs. Examples include securing bolts on valve covers, water pumps, or suspension components.

- Adjustable Components: Blue Loctite is suitable for applications where you may need to make adjustments to the fastener.

- Smaller Fasteners: It’s particularly effective on smaller bolts and screws (typically less than 3/8″ diameter) where the lower bond strength is sufficient.

The Limitations of Blue Loctite

While blue Loctite offers the advantage of removability, it’s not as strong as red Loctite. In high-stress environments or with larger fasteners, it may not provide sufficient holding power.

- Lower Strength: Not suitable for applications subjected to extreme vibration, shock, or chemical exposure where a permanent bond is required.

- Limited Temperature Resistance: May not perform as well as red Loctite at very high temperatures.

- Not Ideal for Permanent Applications: If you need a truly permanent bond, red Loctite is the better choice.

Loctite 243: An Enhanced Blue Threadlocker

Loctite 243 represents an advancement in blue threadlocker technology. While still categorized as a medium-strength, removable threadlocker, Loctite 243 boasts several enhancements over traditional formulations like Loctite 242. Its key advantage lies in its increased tolerance to oil and other surface contaminants. This means that Loctite 243 can provide a reliable bond even on fasteners that aren’t perfectly clean, a common scenario in real-world applications.

Key Features of Loctite 243

- Oil Tolerance: Maintains bond strength on slightly oily surfaces.

- Medium Strength: Removable with hand tools.

- Versatile: Suitable for a wide range of applications.

- Improved Cure Speed: Cures faster than traditional blue threadlockers.

- Thixotropic: Prevents migration after application.

Benefits of Using Loctite 243

The oil tolerance of Loctite 243 translates to several practical benefits. First, it reduces the need for extensive cleaning of fasteners before application, saving time and effort. Second, it provides a more reliable bond in situations where complete cleanliness is difficult or impossible to achieve. Third, it’s a more forgiving option for DIYers and mechanics who may not have access to specialized cleaning equipment.

Comparing Red and Blue Loctite: A Side-by-Side Analysis

To further clarify the differences between red and blue Loctite, here’s a side-by-side comparison:

| Feature | Red Loctite | Blue Loctite |

|---|---|---|

| Strength | High | Medium |

| Removability | Difficult (requires heat) | Easy (with hand tools) |

| Typical Applications | Permanent assemblies, high-stress environments | Serviceable assemblies, adjustable components |

| Temperature Resistance | Higher | Slightly Lower |

| Fastener Size | Best for larger fasteners (3/8″ and up) | Best for smaller fasteners (under 3/8″) |

Application Techniques for Optimal Results

Regardless of whether you choose red or blue Loctite, proper application is crucial for achieving optimal results. Here’s a step-by-step guide:

- Clean the Threads: Remove any dirt, grease, or rust from the threads of both the bolt and the nut or tapped hole. A wire brush and solvent cleaner work well.

- Apply the Threadlocker: Apply a small amount of Loctite to the leading threads of the bolt. A few drops are usually sufficient.

- Assemble the Fastener: Tighten the fastener to the manufacturer’s recommended torque specification.

- Allow to Cure: Allow the Loctite to cure for the recommended time (typically 24 hours) before subjecting the assembly to load or vibration.

Pro Tip: For blind holes (where the bolt doesn’t pass all the way through), apply a few drops of Loctite to the bottom of the hole before inserting the bolt. This will ensure that the threadlocker reaches all the threads.

Real-World Examples and Case Studies

Let’s look at some real-world examples to illustrate the appropriate use of red and blue Loctite:

- Example 1: Securing a Flywheel Bolt (Red Loctite): Flywheel bolts are subjected to extreme stress and vibration. Using red Loctite ensures that they remain securely fastened, preventing catastrophic engine damage. This is a critical application where a permanent bond is essential.

- Example 2: Securing a Water Pump Bolt (Blue Loctite): Water pumps require periodic maintenance and replacement. Using blue Loctite allows for easy removal of the bolts when the time comes, without damaging the threads or the pump housing. This is a situation where removability is paramount.

- Example 3: Securing a Suspension Bolt (Blue Loctite): Suspension components often require adjustments. Blue Loctite allows for easy removal and re-torquing of the bolts as needed.

Debunking Common Myths About Loctite

There are several misconceptions surrounding Loctite. Let’s debunk a few of the most common ones:

- Myth: More Loctite is better. Fact: Applying too much Loctite can actually weaken the bond by preventing proper curing. A thin, even coating is all that’s needed.

- Myth: Loctite is only for automotive applications. Fact: Loctite can be used in a wide range of applications, from securing screws in electronics to preventing leaks in plumbing fittings.

- Myth: Loctite is a substitute for proper torque. Fact: Loctite is designed to supplement, not replace, proper torque. Always tighten fasteners to the manufacturer’s recommended torque specification.

The Takeaway: Choosing the Right Loctite for Your Project

Choosing between red and blue Loctite comes down to the specific requirements of your project. Red Loctite is the choice for permanent assemblies and high-stress environments, while blue Loctite is better suited for applications where disassembly may be required. Understanding the strengths and weaknesses of each type will help you make the right decision and ensure a secure, long-lasting hold.

Before starting your next project, take a moment to assess the factors involved. Will the joint be subjected to high vibration? Will it need to be disassembled in the future? Answering these questions will guide you to the appropriate threadlocker and ensure a successful outcome. Share your experiences with red and blue Loctite in the comments below – your insights can help others make informed decisions!