The Definitive Guide to Cleaning Rods: Selection, Use, and Maintenance

A firearm’s accuracy and longevity are inextricably linked to proper maintenance, and at the heart of that maintenance lies the humble cleaning rod. Far more than a simple stick, the cleaning rod is a precision tool, and understanding its nuances is crucial for any responsible gun owner. Whether you’re a seasoned marksman or a new enthusiast, selecting the right cleaning rod and using it correctly can be the difference between a well-maintained firearm and one prone to malfunctions and diminished accuracy. This comprehensive guide will delve into the world of cleaning rods, exploring their types, materials, proper usage techniques, and essential maintenance practices. We’ll equip you with the knowledge to choose the best cleaning rod for your firearms and maintain them effectively, ensuring peak performance and extending their lifespan.

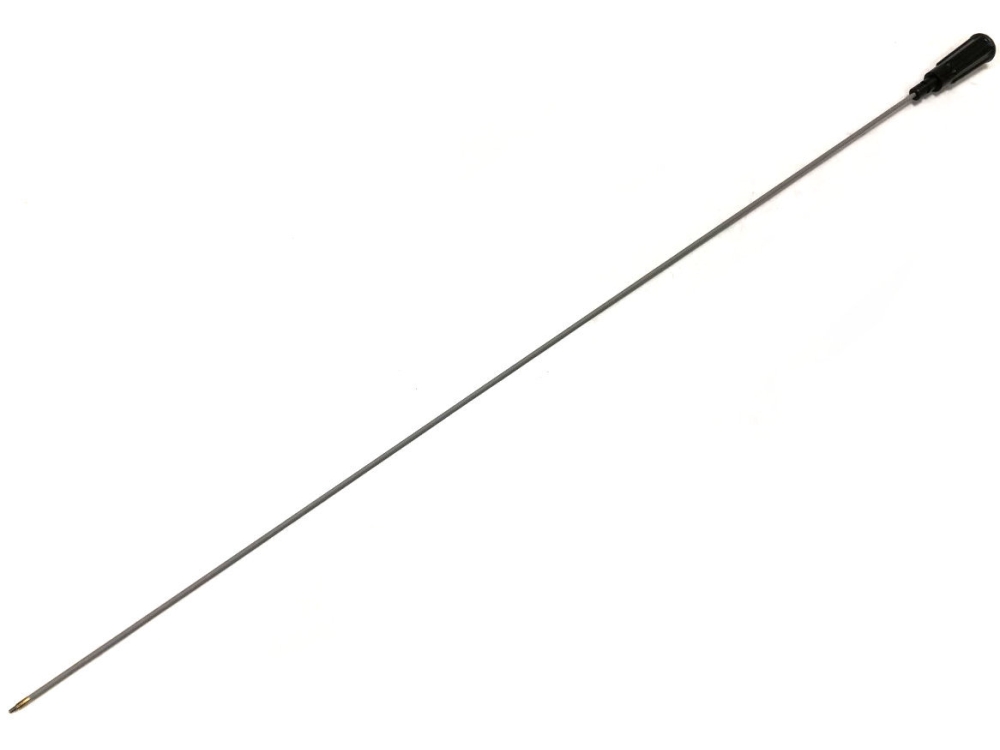

Understanding the Anatomy of a Cleaning Rod

A cleaning rod isn’t just a single piece of metal or plastic. It’s a system composed of several key components, each playing a vital role in the cleaning process. Understanding these components allows for informed selection and effective use.

- Rod Material: The rod itself is typically made of steel, coated steel, brass, aluminum, or carbon fiber. The ideal material balances strength, flexibility, and resistance to scratching the bore.

- Handle: The handle provides a comfortable and secure grip, allowing for controlled movement of the rod. Handles often feature ball bearings or similar mechanisms that allow the rod to rotate freely, following the rifling of the bore.

- Attachments: These are the business end of the cleaning rod, including jags, brushes, and slotted tips, each designed for a specific cleaning task.

- Sections: Many cleaning rods are segmented, allowing for compact storage and adaptability to different barrel lengths.

Choosing the Right Material: A Matter of Bore Integrity

The material of your cleaning rod is paramount. Steel rods, while strong, can potentially damage the bore if not used carefully. Coated steel rods offer a protective layer, reducing the risk of scratching. Brass is softer than steel and generally considered safe for most bores, but it can still pick up grit and transfer it to the bore. Aluminum rods are lightweight but can be easily bent or damaged. Carbon fiber rods are lightweight, strong, and non-abrasive, making them an excellent choice for protecting your firearm’s bore. Our experience shows that carbon fiber or coated steel rods are ideal for preserving the integrity of your firearm’s bore over repeated cleanings.

Handle Design: Ergonomics and Functionality

The handle of a cleaning rod should be comfortable to grip and allow for smooth, controlled movement. A rotating handle is essential, as it allows the rod to follow the rifling of the bore, minimizing friction and preventing damage. Look for handles with ball bearings or similar mechanisms that provide smooth, effortless rotation. Based on expert consensus, a comfortable, rotating handle significantly improves the cleaning process and reduces the risk of damaging the bore.

Selecting the Right Cleaning Rod for Your Firearm

Choosing the appropriate cleaning rod is crucial for effective firearm maintenance. Factors such as the firearm’s caliber, barrel length, and the type of ammunition used all influence the ideal cleaning rod selection.

- Caliber Specificity: Cleaning rods are designed for specific caliber ranges. Using a rod that is too large can damage the bore, while a rod that is too small may not effectively clean the firearm.

- Barrel Length: The cleaning rod must be long enough to pass completely through the barrel. Shorter rods are suitable for handguns and short-barreled rifles, while longer rods are necessary for rifles with longer barrels.

- One-Piece vs. Multi-Piece: One-piece cleaning rods are generally preferred for their strength and reduced risk of bending or breaking. However, multi-piece rods are more compact and easier to store.

Cleaning Rod Length: Avoiding Damage and Ensuring Thoroughness

The length of your cleaning rod is critical. A rod that’s too short won’t allow you to properly clean the entire length of the bore, leaving behind residue and potential corrosion. A rod that’s too long can be unwieldy and increase the risk of bending or damaging the rod itself. Always measure the length of your firearm’s barrel (from the breech face to the muzzle) and choose a cleaning rod that is at least a few inches longer. This ensures that you can fully clean the bore without straining the rod or risking damage.

Caliber Compatibility: Precision Cleaning for Optimal Performance

Using the correct caliber-specific cleaning rod is essential for effective cleaning and preventing damage. A rod that’s too large can exert excessive pressure on the bore, potentially causing scratches or even warping. A rod that’s too small won’t make sufficient contact with the bore’s surface, resulting in incomplete cleaning. Always refer to your firearm’s manual or consult with a gunsmith to determine the correct cleaning rod caliber for your specific firearm. This ensures that you’re using the right tool for the job and protecting your investment.

Essential Cleaning Rod Attachments and Their Uses

A cleaning rod is only as effective as the attachments used with it. Each attachment serves a specific purpose in the cleaning process, and understanding their functions is crucial for thorough firearm maintenance.

- Jags: Jags are used to push patches through the bore, applying cleaning solvents and removing fouling.

- Brushes: Brushes are used to scrub the bore, loosening stubborn deposits of carbon, lead, and copper.

- Slotted Tips: Slotted tips hold patches for applying solvents, oils, or polishing compounds.

- Mops: Mops are used to apply oil or protectants to the bore after cleaning.

Jags: The Foundation of Bore Cleaning

Jags are arguably the most important cleaning rod attachment. They provide a secure and even contact between the cleaning patch and the bore, ensuring effective removal of fouling and residue. Different jag designs are available, including pointed jags and slotted jags. Pointed jags are generally preferred for their ability to center the patch in the bore, while slotted jags are easier to use with pre-cut patches. When selecting a jag, ensure that it is the correct caliber for your firearm and that it is made of a material that won’t damage the bore, such as brass or nylon.

Brushes: Tackling Stubborn Fouling

Brushes are essential for removing stubborn deposits of carbon, lead, and copper that can accumulate in the bore over time. Bronze brushes are commonly used for removing copper fouling, while nylon brushes are suitable for removing carbon and lead. It’s important to use brushes that are specifically designed for firearm cleaning, as other types of brushes may be too abrasive and can damage the bore. Always use a bore solvent in conjunction with a brush to loosen the fouling and facilitate its removal.

Proper Cleaning Techniques for Optimal Firearm Performance

Using a cleaning rod effectively requires proper technique. Rushing the process or using incorrect methods can damage the firearm or fail to adequately clean it.

- Disassembly: Always disassemble the firearm according to the manufacturer’s instructions before cleaning.

- Solvent Application: Apply a bore solvent to the bore using a jag and patch or a slotted tip.

- Brushing: Use a brush to scrub the bore, working from the chamber to the muzzle.

- Patching: Use a jag and clean patches to remove solvent and fouling until the patches come out clean.

- Lubrication: Apply a light coat of gun oil to the bore using a mop or a patch.

- Reassembly: Reassemble the firearm according to the manufacturer’s instructions.

The Importance of Proper Bore Solvent Selection

The choice of bore solvent is critical for effective cleaning and preventing damage to your firearm. Different solvents are designed to remove different types of fouling, such as carbon, lead, copper, and plastic wad residue. Using the wrong solvent can be ineffective or even harmful to the bore. Always consult your firearm’s manual or a gunsmith to determine the appropriate solvent for your specific firearm and the type of ammunition you use. When in doubt, start with a mild solvent and gradually increase its strength as needed. Never use abrasive cleaners or solvents that are not specifically designed for firearm cleaning, as these can damage the bore and reduce accuracy.

Cleaning from Breech to Muzzle: A Best Practice for Bore Integrity

The direction in which you clean your firearm’s bore can significantly impact its longevity and accuracy. Cleaning from the breech (the chamber end) to the muzzle is generally considered the best practice, as it minimizes the risk of damaging the crown of the barrel. The crown is the muzzle’s edge, and any imperfections or damage to it can negatively affect the bullet’s flight path and accuracy. When cleaning from the breech, use a bore guide to protect the chamber and ensure that the cleaning rod is properly aligned. If you must clean from the muzzle, exercise extreme caution to avoid damaging the crown. Always use a muzzle guide to protect the crown and prevent the cleaning rod from rubbing against the bore’s edge.

Maintaining Your Cleaning Rod: Ensuring Longevity and Effectiveness

A cleaning rod is an investment, and proper maintenance is essential to ensure its longevity and effectiveness. Cleaning rods can accumulate dirt, grit, and solvent residue, which can damage the bore if not removed.

- Cleaning: Clean the cleaning rod after each use with a solvent or degreaser.

- Inspection: Inspect the cleaning rod regularly for bends, cracks, or other damage.

- Storage: Store the cleaning rod in a clean, dry place to prevent corrosion.

Preventing Contamination: Keeping Your Cleaning Rod Clean

One of the most overlooked aspects of cleaning rod maintenance is preventing contamination. A dirty cleaning rod can actually do more harm than good, as it can transfer grit and abrasive particles to the bore, potentially causing scratches and wear. Always clean your cleaning rod after each use with a solvent or degreaser to remove any fouling or residue. Use a soft cloth or brush to thoroughly clean the rod, paying particular attention to the threads and handle. Allow the rod to dry completely before storing it to prevent corrosion.

Storage Solutions: Protecting Your Investment

Proper storage is essential for protecting your cleaning rod from damage and corrosion. Store your cleaning rod in a clean, dry place, away from direct sunlight and extreme temperatures. A dedicated cleaning rod case or storage tube is ideal for protecting the rod from dust, dirt, and moisture. If you don’t have a case or tube, you can wrap the rod in a soft cloth or towel to protect it from scratches and dents. Avoid storing your cleaning rod in a damp or humid environment, as this can promote corrosion and rust. By taking the time to properly store your cleaning rod, you can ensure that it remains in good condition for years to come.

Advanced Cleaning Techniques and Considerations

Beyond the basic cleaning procedures, several advanced techniques can further enhance firearm maintenance and ensure optimal performance. These techniques often involve specialized tools and solvents, and they require a more in-depth understanding of firearm mechanics.

- Copper Fouling Removal: Specialized solvents and brushes are available for removing stubborn copper fouling.

- Lead Fouling Removal: Lead fouling can be particularly difficult to remove, requiring specialized solvents and techniques.

- Bore Scoring Inspection: Using a bore scope to inspect the bore for scoring or damage can help identify potential problems early on.

Utilizing Bore Scopes for Detailed Inspection

A bore scope is a valuable tool for inspecting the interior of your firearm’s barrel. It allows you to visually assess the condition of the bore, identifying any signs of wear, corrosion, or damage. A bore scope can also help you determine the effectiveness of your cleaning procedures, ensuring that you’re removing all fouling and residue. When using a bore scope, pay close attention to the rifling, looking for any signs of wear or damage. Also, inspect the bore for any signs of corrosion or pitting. If you notice any significant problems, consult with a gunsmith to determine the appropriate course of action.

Addressing Stubborn Fouling: Advanced Solvent Strategies

Sometimes, standard bore solvents are not enough to remove stubborn fouling, particularly copper and lead. In these cases, specialized solvents may be necessary. Copper solvents typically contain ammonia or other chemicals that dissolve copper deposits. Lead solvents typically contain chemicals that break down lead compounds. When using specialized solvents, always follow the manufacturer’s instructions carefully and wear appropriate safety gear, such as gloves and eye protection. It’s also important to neutralize the solvent after use to prevent it from damaging the bore. Use a mild solvent or bore cleaner to remove any remaining residue and then apply a light coat of gun oil to protect the bore from corrosion.

Choosing the Right Cleaning Rod: A Summary of Key Considerations

Selecting the right cleaning rod is a crucial step in maintaining your firearms and ensuring their longevity and accuracy. By understanding the different types of cleaning rods, their components, and the proper techniques for using them, you can effectively clean your firearms and protect your investment. Remember to choose a cleaning rod that is appropriate for the caliber and barrel length of your firearm, and always use the correct attachments for the task at hand. Proper maintenance of your cleaning rod is also essential to ensure its longevity and effectiveness. By following these guidelines, you can keep your firearms in top condition and enjoy them for many years to come.

Maintaining Your Firearm: A Final Word

The cleaning rod is an indispensable tool for firearm maintenance, and understanding its proper use is essential for any responsible gun owner. By selecting the right cleaning rod, utilizing appropriate cleaning techniques, and maintaining your equipment diligently, you can ensure the longevity, accuracy, and safe operation of your firearms. Share your experiences with cleaning rods in the comments below, and let’s continue to learn and improve our firearm maintenance practices together.