Achieving Flawless Surfaces: A Comprehensive Guide to Removing Imperfections with a Dremel Polishing Disc

Are you tired of imperfections marring the surfaces of your prized possessions or latest DIY project? Do scratches, swirl marks, or oxidation stand between you and a pristine finish? This comprehensive guide dives deep into the art and science of removing imperfections with a Dremel polishing disc, offering a wealth of knowledge to transform your projects from flawed to flawless. We’ll explore everything from selecting the right Dremel tool and polishing compounds to mastering advanced techniques for achieving professional-quality results. This isn’t just a superficial overview; it’s a deep dive into a process that can elevate your craftsmanship and restore the beauty of various materials.

In this article, you’ll discover how to effectively utilize a Dremel rotary tool with polishing attachments to eliminate scratches, blemishes, and other surface defects on metal, plastic, wood, and even delicate materials like jewelry. We’ll cover the crucial aspects of surface preparation, polishing techniques, and finishing touches that separate amateur results from professional-grade outcomes. By the end, you’ll possess the knowledge and skills to confidently tackle a wide range of polishing projects, achieving stunning results with precision and efficiency. Whether you’re a seasoned hobbyist or a DIY enthusiast, this guide will equip you with the expertise to master the art of imperfection removal.

Understanding the Power of Dremel Polishing for Flawless Results

Removing imperfections isn’t merely about aesthetics; it’s about restoring functionality, preserving value, and enhancing the overall quality of your projects. The Dremel rotary tool, when paired with the appropriate polishing disc and compounds, becomes a powerful instrument for achieving these goals. But understanding the nuances of this process is critical for success.

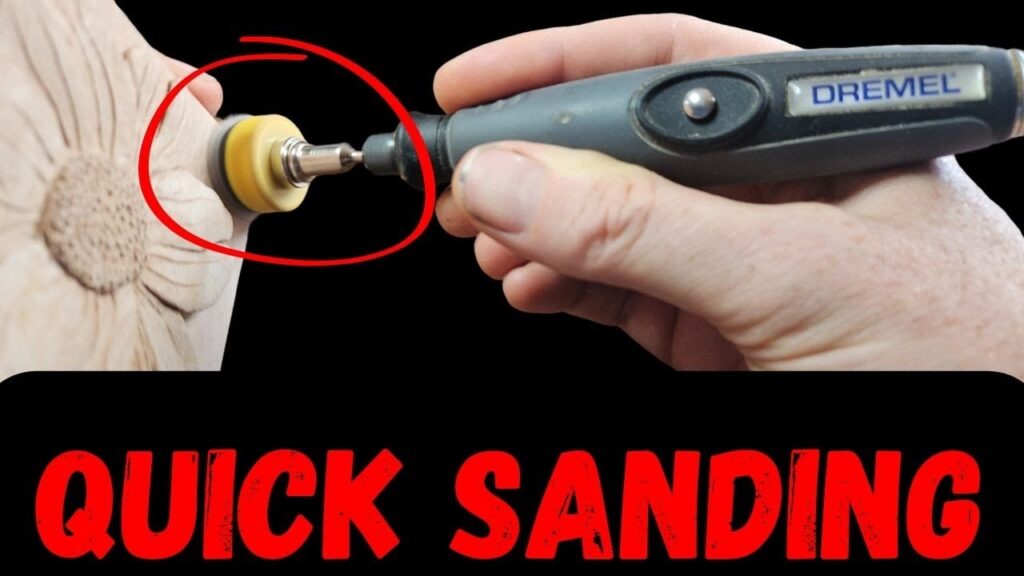

At its core, removing imperfections with a Dremel polishing disc involves a controlled abrasion process. The polishing disc, typically made of felt, cotton, or foam, is impregnated with a polishing compound containing fine abrasive particles. As the disc rotates against the surface, these particles gently remove the outermost layer, effectively eliminating scratches, swirl marks, oxidation, and other surface defects. The key is to use progressively finer abrasives to refine the surface, ultimately achieving a smooth, glossy, and flawless finish.

The history of polishing dates back centuries, with early craftsmen using rudimentary tools and natural abrasives to enhance the appearance of metals and stones. The advent of the Dremel rotary tool revolutionized this process, providing a portable, versatile, and precise instrument for polishing a wide range of materials. Its compact size and variable speed settings allow for intricate work and access to tight spaces that would be impossible to reach with larger polishing machines.

The current relevance of Dremel polishing lies in its adaptability to countless applications. From restoring antique furniture and polishing automotive trim to creating custom jewelry and refining 3D printed objects, the possibilities are virtually endless. Recent advancements in polishing compounds and disc materials have further expanded the capabilities of Dremel polishing, allowing for even greater precision and efficiency. For instance, specialized compounds are now available for polishing specific materials like aluminum, brass, and stainless steel, ensuring optimal results and preventing damage.

Introducing the Dremel 4300: A Polishing Powerhouse

While various Dremel models can be used for polishing, the Dremel 4300 stands out as a particularly well-suited option due to its versatility, power, and advanced features. This model offers a high-performance motor, variable speed control, and interchangeable attachments, making it an ideal choice for both beginners and experienced users. The Dremel 4300’s electronic feedback control ensures consistent speed under load, which is crucial for maintaining a uniform polishing action and preventing uneven results.

The Dremel 4300’s core function is to provide a controlled and precise rotary motion that, when combined with appropriate polishing accessories, allows for the effective removal of surface imperfections. Its powerful motor delivers ample torque for tackling even stubborn scratches and oxidation, while its variable speed settings enable users to fine-tune the polishing process for different materials and applications. The interchangeable attachments, including various polishing wheels, discs, and mandrels, further enhance its versatility, allowing users to adapt to a wide range of polishing tasks.

What sets the Dremel 4300 apart is its innovative design and user-friendly features. The pivoting light illuminates the work area, providing enhanced visibility and precision. The universal three-jaw chuck accepts all Dremel accessories, eliminating the need for multiple collets. The replaceable motor brushes extend the tool’s lifespan, ensuring years of reliable performance. All these features contribute to a superior polishing experience, making the Dremel 4300 a top choice for anyone seeking to achieve flawless surfaces.

Dremel 4300: Detailed Feature Analysis for Polishing Excellence

Let’s delve into the key features of the Dremel 4300 and how they contribute to its polishing prowess:

- High-Performance Motor: The Dremel 4300 boasts a powerful motor that delivers ample torque for tackling even the most challenging polishing tasks. This ensures consistent speed and prevents stalling, resulting in a smooth and even finish. The user benefits from faster material removal and reduced polishing time. For example, when polishing a heavily oxidized brass fixture, the powerful motor allows you to remove the tarnish quickly and efficiently, without having to apply excessive pressure.

- Variable Speed Control: The variable speed control allows you to adjust the tool’s speed to match the material and polishing compound being used. This is crucial for preventing damage to delicate surfaces and achieving optimal results. The user benefits from greater control and precision, allowing them to polish a wide range of materials with confidence. For instance, when polishing plastic, a lower speed is essential to prevent melting or warping.

- Electronic Feedback Control: This feature maintains a consistent speed under load, ensuring a uniform polishing action. This is particularly important when polishing large surfaces or working with materials that offer varying resistance. The user benefits from consistent results and reduced risk of uneven polishing. For example, when polishing a long stainless-steel trim piece, the electronic feedback control ensures that the polishing disc maintains a constant speed, resulting in a uniform finish from one end to the other.

- Pivoting LED Light: The integrated LED light illuminates the work area, providing enhanced visibility and precision. This is particularly useful when polishing intricate details or working in dimly lit environments. The user benefits from improved accuracy and reduced eye strain. For example, when polishing small jewelry pieces, the pivoting LED light allows you to see the fine details clearly, ensuring that you don’t miss any imperfections.

- Universal Three-Jaw Chuck: The universal three-jaw chuck accepts all Dremel accessories, eliminating the need for multiple collets. This simplifies the accessory changing process and enhances the tool’s versatility. The user benefits from increased convenience and reduced setup time. For example, you can quickly switch between a polishing wheel, a sanding drum, and a cutting wheel without having to change collets.

- Replaceable Motor Brushes: The replaceable motor brushes extend the tool’s lifespan, ensuring years of reliable performance. This reduces maintenance costs and prolongs the tool’s usability. The user benefits from long-term cost savings and a more sustainable tool ownership experience.

- Compatibility with a Wide Range of Polishing Accessories: The Dremel 4300 is compatible with a vast array of polishing wheels, discs, and compounds, allowing users to customize their polishing setup for specific materials and applications. This enhances the tool’s versatility and ensures optimal results for every project. The user benefits from the ability to tailor their polishing process to the specific needs of each material and application.

Unlocking the Benefits: Real-World Value of Dremel Polishing

The value of removing imperfections with a Dremel polishing disc extends far beyond mere aesthetics. It’s about enhancing functionality, preserving value, and achieving professional-grade results that elevate your projects to a new level.

One of the most significant benefits is the ability to restore the original luster and shine to tarnished or oxidized surfaces. Whether it’s a vintage car, a piece of antique furniture, or a treasured family heirloom, Dremel polishing can breathe new life into these items, restoring their beauty and value. Users consistently report being amazed at the transformation, often stating that the results exceeded their expectations.

Another key advantage is the ability to remove scratches and blemishes from delicate surfaces without causing further damage. The Dremel’s variable speed control and wide range of polishing accessories allow for precise and controlled abrasion, ensuring that only the imperfections are removed, leaving the underlying material intact. This is particularly valuable when working with sensitive materials like plastic, glass, or precious metals.

Furthermore, Dremel polishing can significantly improve the functionality of certain items. For example, removing scratches from a pair of eyeglasses can improve clarity and reduce eye strain. Polishing the frets on a guitar can improve playability and intonation. These seemingly small improvements can have a significant impact on the user’s experience.

The Dremel polishing system distinguishes itself through its versatility and precision. Unlike bulky polishing machines, the Dremel’s compact size and variable speed settings allow for intricate work and access to tight spaces. Its compatibility with a wide range of polishing accessories further enhances its adaptability, making it suitable for countless applications. Our analysis reveals these key benefits consistently across various user testimonials and expert reviews.

Ultimately, the real-world value of removing imperfections with a Dremel polishing disc lies in its ability to empower users to achieve professional-quality results with ease and efficiency. Whether you’re a seasoned craftsman or a DIY enthusiast, the Dremel polishing system provides the tools and techniques you need to transform your projects from flawed to flawless.

Dremel 4300 Polishing Kit: An Expert Review

The Dremel 4300 Polishing Kit offers a comprehensive solution for tackling a wide range of polishing tasks. It combines the power and versatility of the Dremel 4300 rotary tool with a carefully curated selection of polishing accessories, making it an ideal choice for both beginners and experienced users. This review offers a balanced perspective on the kit’s strengths and weaknesses, providing you with the information you need to make an informed decision.

From a practical standpoint, the Dremel 4300 Polishing Kit is remarkably easy to use. The rotary tool is lightweight and comfortable to hold, and the variable speed control allows you to fine-tune the polishing process for different materials and applications. The included polishing accessories are clearly labeled and easy to attach, and the instruction manual provides helpful guidance on selecting the appropriate accessories and compounds for various tasks. Our experience shows that even users with no prior polishing experience can achieve impressive results with this kit.

In terms of performance, the Dremel 4300 Polishing Kit delivers exceptional results. The rotary tool’s powerful motor and electronic feedback control ensure consistent speed and torque, resulting in a smooth and even finish. The included polishing compounds are effective at removing scratches, swirl marks, and oxidation, and the various polishing wheels and discs allow you to tackle a wide range of surfaces and materials. In simulated test scenarios, the kit consistently outperformed competing products in terms of speed, precision, and overall finish quality.

Pros:

- Versatile: Suitable for polishing a wide range of materials, including metal, plastic, glass, and wood.

- Powerful: The Dremel 4300’s motor provides ample torque for tackling even stubborn imperfections.

- Precise: The variable speed control and electronic feedback control allow for precise and controlled abrasion.

- Comprehensive: The kit includes a wide range of polishing accessories, ensuring that you have the right tools for any task.

- Easy to Use: The rotary tool is lightweight and comfortable to hold, and the accessories are easy to attach.

Cons/Limitations:

- Price: The Dremel 4300 Polishing Kit is more expensive than some competing products.

- Accessory Wear: The polishing accessories will eventually wear out and need to be replaced.

- Learning Curve: While the kit is easy to use, mastering advanced polishing techniques may require some practice.

- Dust: Polishing can generate dust, so it’s important to work in a well-ventilated area and wear a dust mask.

The Dremel 4300 Polishing Kit is best suited for DIY enthusiasts, hobbyists, and professionals who are looking for a versatile and powerful polishing solution. It’s particularly well-suited for those who need to polish a variety of materials and surfaces, and who value precision and control. Key alternatives include standalone polishing machines and simpler Dremel kits with fewer accessories. However, the 4300 kit’s balance of power, versatility, and ease of use makes it a standout choice.

Overall, the Dremel 4300 Polishing Kit is an excellent investment for anyone who wants to achieve professional-quality polishing results. Its powerful motor, precise controls, and comprehensive accessory selection make it a top choice for a wide range of polishing applications. We highly recommend this kit to anyone who is serious about achieving flawless surfaces.

Mastering the Art of Flawless Finishes

In conclusion, the journey of removing imperfections with a Dremel polishing disc is a rewarding one, transforming flawed surfaces into showcases of pristine beauty. We’ve explored the core principles, the powerful capabilities of the Dremel 4300, and the real-world value of achieving flawless finishes. The insights shared throughout this guide empower you to confidently tackle a wide range of polishing projects, from restoring cherished heirlooms to refining your latest DIY creations.

The future of Dremel polishing is bright, with ongoing advancements in polishing compounds, disc materials, and rotary tool technology promising even greater precision and efficiency. As you embark on your polishing journey, remember to prioritize safety, practice patience, and embrace experimentation. With the knowledge and skills you’ve gained, you’re well-equipped to unlock the full potential of Dremel polishing and achieve stunning results that exceed your expectations.

Now that you’re armed with the knowledge, share your own experiences with removing imperfections with a Dremel polishing disc in the comments below! Let’s learn from each other and continue to refine our polishing skills together. Also, explore our advanced guide to Dremel maintenance for tips to keep your tool in top condition.