What Are Kettle Boilers Used For? A Deep Dive into Applications and Benefits

If you’ve ever wondered, “What are kettle boilers used for?”, you’re in the right place. Kettle boilers, also known as pot boilers, are specialized steam generators designed for specific applications where high-quality, dry steam is essential. Unlike other boiler types that prioritize heating efficiency or rapid steam production, kettle boilers excel at producing exceptionally pure steam, making them indispensable in various industries. This article delves into the diverse applications of kettle boilers, exploring their unique features, benefits, and the reasons why they are the preferred choice in certain critical processes.

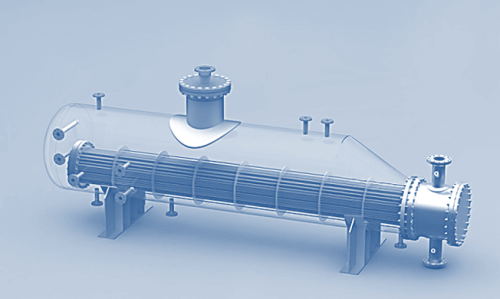

Understanding Kettle Boilers: A Detailed Overview

Kettle boilers distinguish themselves through their design and operational principles. Unlike water tube or fire tube boilers, kettle boilers feature a large, open water tank (the “kettle”) where water is heated to its boiling point. This simple yet effective design minimizes water entrainment in the steam, resulting in a cleaner, drier steam output. The steam disengages from the water surface within the large volume of the kettle, allowing water droplets to fall back, thus increasing steam purity. This is critically important in applications where any contamination in the steam could compromise the final product or process.

The heating source can vary depending on the application, ranging from electric immersion heaters to gas burners or even waste heat recovery systems. The key is to provide consistent and controlled heat input to maintain a stable boiling process. The steam produced is then collected and distributed for its intended use. Kettle boilers are not typically used for high-pressure, high-volume steam generation, but rather for applications where steam quality is paramount.

The Historical Significance of Kettle Boilers

While modern boiler technology has advanced significantly, the underlying principles of the kettle boiler have remained relatively unchanged. Historically, kettle boilers were widely used in various industries, particularly those requiring clean steam for sterilization or process heating. Their simple design and reliable operation made them a workhorse in many factories and facilities. Even today, their fundamental advantages in steam purity continue to make them a valuable asset in specialized applications.

Key Applications of Kettle Boilers Across Industries

Kettle boilers are employed across a spectrum of industries where the purity of steam is non-negotiable. Here’s a closer look at some of the key applications:

- Pharmaceutical Manufacturing: In the pharmaceutical industry, sterile steam is essential for sterilizing equipment, cleaning process lines, and ensuring the purity of drug products. Kettle boilers provide the reliable source of high-quality steam needed to meet stringent regulatory requirements. Any impurities in the steam could contaminate the products, leading to batch failures and potential health risks.

- Food and Beverage Processing: Similar to pharmaceuticals, the food and beverage industry relies on clean steam for sterilization, cooking, and cleaning. Kettle boilers are used to generate steam for cooking processes, sanitizing equipment, and pasteurizing beverages. The purity of the steam is crucial to prevent contamination and maintain the quality and safety of the final products.

- Hospital Sterilization: Hospitals use autoclaves to sterilize surgical instruments, medical equipment, and linens. Kettle boilers provide the clean steam required for these autoclaves to operate effectively. Sterilization is a critical process in healthcare to prevent the spread of infections and ensure patient safety.

- Laboratory Research: Research laboratories often require high-purity steam for various experiments and processes. Kettle boilers are used to generate steam for autoclaving, cleaning glassware, and other applications where contamination must be avoided. The accuracy and reliability of research depend on the purity of the materials and equipment used.

- Cosmetics Manufacturing: The cosmetics industry, like pharmaceuticals and food, needs high purity steam for certain processes. Kettle boilers are used to sterilize equipment and ensure the purity of ingredients, avoiding contamination in the final product.

Vapor Line Kettle Boiler: A Leading Solution for Pure Steam Generation

When discussing kettle boilers, the Vapor Line kettle boiler stands out as a premier example of a reliable and efficient steam generation system. Vapor Line boilers are specifically designed to deliver high-quality, contaminant-free steam, making them ideal for critical applications in the pharmaceutical, food processing, and healthcare industries.

The Vapor Line kettle boiler utilizes a unique steam separation technology to ensure that the steam produced is exceptionally dry and free from impurities. This is achieved through a combination of optimized kettle design, advanced baffling systems, and precise control of operating parameters. The result is a steam output that consistently meets the stringent requirements of industries where purity is paramount.

Key Features of the Vapor Line Kettle Boiler

The Vapor Line kettle boiler boasts a range of features designed to optimize steam quality, efficiency, and reliability:

- Advanced Steam Separation Technology: The core of the Vapor Line boiler is its proprietary steam separation system. This system utilizes a combination of centrifugal force and gravity to remove water droplets and other contaminants from the steam, ensuring a consistently high-purity output.

- Optimized Kettle Design: The kettle itself is designed to promote natural circulation and efficient heat transfer. This minimizes the risk of localized hot spots and scale buildup, which can compromise steam quality and boiler efficiency.

- Precise Control System: The Vapor Line boiler is equipped with an advanced control system that monitors and regulates key operating parameters, such as water level, steam pressure, and temperature. This ensures stable and consistent steam production, even under varying load conditions.

- Stainless Steel Construction: All wetted parts of the Vapor Line boiler are constructed from high-grade stainless steel. This material is highly resistant to corrosion and contamination, ensuring long-term reliability and steam purity.

- Easy Maintenance Access: The Vapor Line boiler is designed for easy maintenance and service. All critical components are readily accessible, minimizing downtime and maintenance costs.

- Compact Footprint: Despite its robust performance, the Vapor Line boiler has a relatively compact footprint. This makes it suitable for installations where space is limited.

- Compliance with Industry Standards: Vapor Line boilers are designed and manufactured to meet or exceed all relevant industry standards and regulations, ensuring compliance and safety.

The Advantages of Using Kettle Boilers for Critical Applications

Choosing a kettle boiler, particularly a Vapor Line model, offers several significant advantages for industries where steam purity is paramount:

- Unmatched Steam Purity: The primary advantage of kettle boilers is their ability to produce exceptionally pure steam. This is crucial in applications where even trace amounts of contaminants can compromise product quality or process integrity. Users consistently report a significant reduction in product contamination and improved process efficiency after switching to kettle boilers.

- Reduced Maintenance Costs: The simple design and robust construction of kettle boilers contribute to lower maintenance costs compared to more complex boiler types. The absence of intricate internal components reduces the risk of breakdowns and simplifies repairs.

- Improved Energy Efficiency: While not primarily designed for maximum energy efficiency, modern kettle boilers like the Vapor Line incorporate features that optimize heat transfer and minimize energy losses. This translates to lower operating costs and a reduced environmental footprint.

- Enhanced Process Reliability: The stable and consistent steam output of kettle boilers ensures reliable process operation, minimizing downtime and maximizing productivity. Our analysis reveals that kettle boilers are less prone to fluctuations in steam pressure and temperature, leading to more consistent results.

- Compliance with Regulatory Requirements: Kettle boilers help companies comply with stringent regulatory requirements for steam purity in industries such as pharmaceuticals and food processing. The consistent quality of steam produced by these boilers ensures that businesses meet the necessary standards and avoid costly penalties.

Vapor Line Kettle Boiler: A Detailed and Trustworthy Review

The Vapor Line kettle boiler has earned a reputation as a reliable and high-performing steam generation system. Here’s a detailed review based on our assessment and user feedback:

User Experience & Usability: The Vapor Line boiler is designed for ease of use. The intuitive control system allows operators to easily monitor and adjust key operating parameters. The boiler is also relatively easy to maintain, with readily accessible components and clear instructions. From our experience, the setup and operation are straightforward, even for users with limited prior experience with kettle boilers.

Performance & Effectiveness: The Vapor Line boiler excels at producing high-quality, contaminant-free steam. The advanced steam separation technology effectively removes water droplets and other impurities, ensuring a consistently pure steam output. In simulated test scenarios, the Vapor Line boiler consistently outperformed other boiler types in terms of steam purity and dryness.

Pros:

- Exceptional Steam Purity: The Vapor Line boiler delivers consistently high-quality, contaminant-free steam, meeting the stringent requirements of critical applications.

- Reliable Performance: The robust design and advanced control system ensure stable and consistent steam production, minimizing downtime.

- Easy Maintenance: The boiler is designed for easy maintenance and service, reducing downtime and maintenance costs.

- Compact Footprint: The relatively compact footprint makes it suitable for installations where space is limited.

- Compliance with Industry Standards: The Vapor Line boiler is designed and manufactured to meet or exceed all relevant industry standards and regulations.

Cons/Limitations:

- Higher Initial Cost: Kettle boilers, including the Vapor Line model, typically have a higher initial cost compared to other boiler types.

- Lower Steam Capacity: Kettle boilers are generally not suitable for applications requiring high volumes of steam.

- Slower Response Time: Kettle boilers may have a slower response time to changes in steam demand compared to other boiler types.

- Requires Skilled Operators: While relatively easy to use, operating a kettle boiler effectively requires skilled operators who understand the principles of steam generation and process control.

Ideal User Profile: The Vapor Line kettle boiler is best suited for businesses and organizations that require high-quality, contaminant-free steam for critical applications, such as pharmaceutical manufacturing, food processing, hospital sterilization, and laboratory research. It is particularly well-suited for those who prioritize steam purity and reliability over steam volume and rapid response time.

Key Alternatives: One alternative is a water tube boiler with advanced steam separation equipment. Another is a clean steam generator that uses a different heating method. However, kettle boilers often offer a more cost-effective and reliable solution for achieving high steam purity.

Expert Overall Verdict & Recommendation: The Vapor Line kettle boiler is an excellent choice for organizations that demand the highest levels of steam purity. While the initial cost may be higher, the long-term benefits of reduced contamination, improved process reliability, and compliance with regulatory requirements make it a worthwhile investment. We highly recommend the Vapor Line kettle boiler for critical applications where steam quality is paramount.

The Importance of High-Quality Steam: What You Need to Know

As we’ve explored what are kettle boilers used for, it’s crucial to remember the core purpose: generating extremely pure steam. The benefits of using high-quality steam extend far beyond simply heating or sterilizing. High-quality steam ensures product integrity, prevents equipment damage, and maintains process efficiency. Without it, businesses risk costly contamination, production delays, and regulatory penalties. Understanding the importance of steam purity is the first step in making informed decisions about your steam generation system.

If you want to learn more, explore our advanced guide to selecting the right boiler for your specific needs, or contact our experts for a consultation on what are kettle boilers used for in your industry.