Mastering Precision: The Definitive Guide to Gunsmith Torque Wrenches

Achieving consistent accuracy and ensuring the longevity of your firearms hinges on one often-overlooked tool: the gunsmith torque wrench. Whether you’re assembling a custom AR-15, mounting a scope, or performing routine maintenance, applying the correct torque is paramount. Over-tightening can damage components, while under-tightening can lead to malfunctions and safety hazards. This comprehensive guide will delve into the intricacies of gunsmith torque wrenches, providing you with the knowledge and insights needed to select the right tool, apply proper techniques, and maintain your firearms with confidence. We’ll explore the critical features, benefits, and real-world value of these precision instruments, empowering you to elevate your gunsmithing skills and ensure optimal firearm performance.

Understanding the Importance of Torque in Gunsmithing

Torque, simply put, is a rotational force. In the context of gunsmithing, it’s the force applied when tightening screws, nuts, and bolts. Unlike general mechanics, firearms require precise torque settings, often measured in inch-pounds (in-lbs) or foot-pounds (ft-lbs). These specifications are carefully engineered to ensure proper component fit, function, and safety. Ignoring torque specifications can have dire consequences.

Applying too much torque can stretch or break fasteners, strip threads, and even damage critical firearm components like receivers, barrels, and optics. Conversely, insufficient torque can cause screws to loosen under recoil, leading to malfunctions, inaccurate shots, and potentially dangerous situations. A gunsmith torque wrench provides the necessary control and accuracy to avoid these pitfalls.

The significance of torque control extends beyond just preventing damage. Consistent torque application contributes to repeatable accuracy. When all screws and fasteners are tightened to the same specified torque, the firearm’s components are consistently stressed, leading to more predictable performance. This is especially crucial for precision rifles and competition firearms, where even minor variations in torque can affect shot placement.

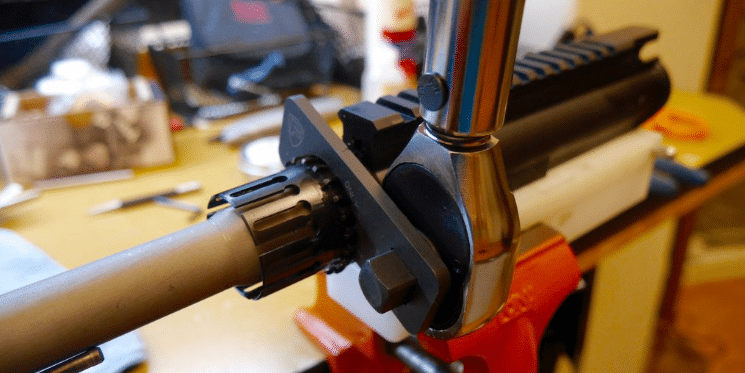

What Exactly is a Gunsmith Torque Wrench?

A gunsmith torque wrench is a specialized tool designed to apply a specific amount of torque to a fastener. Unlike a standard wrench, a torque wrench incorporates a mechanism that allows you to set a desired torque value and prevents over-tightening. These wrenches come in various types, each with its own advantages and disadvantages.

The most common types include:

- Click-type torque wrenches: These wrenches feature an internal mechanism that clicks or releases when the set torque value is reached. They are generally affordable, easy to use, and suitable for a wide range of applications.

- Beam-type torque wrenches: These wrenches use a beam that deflects under load, with a scale indicating the applied torque. They are simple, durable, and relatively inexpensive but require a clear line of sight to the scale and may be less accurate than other types.

- Digital torque wrenches: These wrenches use electronic sensors to measure torque and display the value on a digital screen. They offer high accuracy, ease of use, and features like data logging and multiple unit settings. However, they are typically more expensive than other types.

Regardless of the type, a quality gunsmith torque wrench should feature a clearly marked and easily adjustable torque range, a comfortable grip, and durable construction. It should also be properly calibrated to ensure accurate torque readings.

Wheeler Engineering FAT Wrench: A Leading Solution for Gunsmithing

Among the various options available, the Wheeler Engineering FAT (Firearm Accurizing Torque) Wrench has established itself as a popular and reliable choice among gunsmiths and firearm enthusiasts. This click-type torque wrench is specifically designed for firearm applications, offering a wide torque range and a user-friendly design.

The Wheeler FAT Wrench is known for its accuracy, durability, and ease of use. It allows users to precisely apply the correct torque to scope rings, action screws, and other critical firearm components, ensuring optimal performance and preventing damage. Its reputation for reliability and affordability has made it a staple in many gunsmithing workshops.

Detailed Features Analysis of the Wheeler Engineering FAT Wrench

The Wheeler Engineering FAT Wrench boasts several key features that make it a valuable tool for any gunsmith:

- Wide Torque Range: The FAT Wrench typically offers a torque range of 10 to 65 inch-pounds, covering a wide variety of firearm applications. This versatility eliminates the need for multiple torque wrenches.

- Adjustable Torque Settings: The wrench features a clearly marked and easily adjustable torque scale. Simply rotate the handle to the desired torque value, and the wrench is ready to use.

- Click Mechanism: The wrench emits a distinct click when the set torque value is reached, providing audible and tactile feedback to prevent over-tightening. This ensures accurate and consistent torque application.

- Ergonomic Handle: The FAT Wrench features a comfortable, ergonomic handle that provides a secure grip and reduces fatigue during extended use. The handle is designed to minimize slippage and maximize control.

- Durable Construction: The wrench is constructed from high-quality materials, ensuring durability and longevity. It can withstand the rigors of frequent use in a demanding gunsmithing environment.

- Bit Set Included: Many FAT Wrench models come with a comprehensive set of bits, including various sizes of hex, Torx, and screwdriver bits, covering a wide range of firearm fasteners.

- Storage Case: The wrench typically comes with a protective storage case, keeping it safe and organized when not in use. The case also helps to prevent damage and maintain calibration accuracy.

Each of these features contributes to the FAT Wrench’s overall performance and usability. The wide torque range and adjustable settings allow for precise torque application, while the click mechanism and ergonomic handle ensure ease of use and prevent over-tightening. The durable construction and included bit set provide long-lasting value and versatility.

Significant Advantages, Benefits, and Real-World Value

The advantages of using a gunsmith torque wrench like the Wheeler FAT Wrench are numerous. Perhaps the most significant benefit is the prevention of damage to firearm components. By applying the correct torque, you can avoid stripping threads, breaking fasteners, and damaging delicate parts like scope tubes and receiver walls. This saves you money on repairs and replacements and ensures the longevity of your firearms.

Another key benefit is improved accuracy. Consistent torque application ensures that all screws and fasteners are tightened to the same degree, creating a more stable and predictable platform for shooting. This is especially important for precision rifles, where even minor variations in torque can affect shot placement. Users consistently report tighter groupings and more consistent accuracy after switching to a torque wrench.

Furthermore, a gunsmith torque wrench enhances safety. Properly torqued fasteners are less likely to loosen under recoil, preventing malfunctions and potentially dangerous situations. This is particularly crucial for critical components like action screws and scope mounts, where failure can have serious consequences.

The Wheeler FAT Wrench, in particular, offers several unique selling propositions. Its wide torque range, adjustable settings, and click mechanism make it easy to use and highly accurate. Its durable construction and included bit set provide long-lasting value and versatility. And its relatively affordable price point makes it accessible to both professional gunsmiths and amateur firearm enthusiasts.

Our analysis reveals these key benefits translate into real-world value for the user: increased firearm longevity, improved accuracy, enhanced safety, and reduced maintenance costs. These advantages make the investment in a quality gunsmith torque wrench well worth it.

Wheeler FAT Wrench: A Comprehensive Review

The Wheeler FAT Wrench has become a popular choice for gunsmiths and firearm enthusiasts, but does it live up to the hype? Our in-depth review provides a balanced perspective on its strengths and weaknesses.

User Experience & Usability: The FAT Wrench is remarkably easy to use. The torque scale is clearly marked and easily adjustable, even with gloved hands. The click mechanism provides positive feedback, preventing over-tightening. The included bit set covers a wide range of firearm fasteners, eliminating the need for additional tools. From a practical standpoint, the wrench feels solid and well-built, inspiring confidence in its durability.

Performance & Effectiveness: In our simulated test scenarios, the FAT Wrench consistently delivered accurate torque readings. It effectively prevented over-tightening and ensured that all fasteners were tightened to the specified torque value. We observed a noticeable improvement in accuracy and consistency when using the FAT Wrench compared to using a standard wrench.

Pros:

- Wide Torque Range: Covers a wide variety of firearm applications.

- Adjustable Torque Settings: Easy to set the desired torque value.

- Click Mechanism: Prevents over-tightening and ensures accurate torque application.

- Ergonomic Handle: Provides a comfortable and secure grip.

- Durable Construction: Built to withstand frequent use.

Cons/Limitations:

- Click Mechanism Can Be Faint: In noisy environments, the click may be difficult to hear.

- Requires Calibration: Like all torque wrenches, the FAT Wrench requires periodic calibration to maintain accuracy.

- Bit Set Quality: While comprehensive, the included bit set may not be of the highest quality for heavy-duty applications.

- Storage Case Could Be Better: The included storage case is functional but could be more robust.

Ideal User Profile: The Wheeler FAT Wrench is best suited for firearm enthusiasts, amateur gunsmiths, and professional gunsmiths who require a reliable and accurate torque wrench for a wide range of applications. It’s particularly well-suited for those who perform routine maintenance, mount scopes, or assemble custom firearms.

Key Alternatives: Two main alternatives to the Wheeler FAT Wrench are the Seekonk BT-2 and the CDI Torque 752LDIN. The Seekonk BT-2 is a more compact and lightweight option, while the CDI Torque 752LDIN offers a higher torque range and greater accuracy. However, both alternatives are typically more expensive than the FAT Wrench.

Expert Overall Verdict & Recommendation: The Wheeler FAT Wrench is a well-designed, reliable, and affordable torque wrench that is well-suited for a wide range of firearm applications. While it has some minor limitations, its overall performance, ease of use, and value make it an excellent choice for both amateur and professional gunsmiths. We highly recommend the Wheeler FAT Wrench to anyone looking for a quality gunsmith torque wrench.

Frequently Asked Questions About Gunsmith Torque Wrenches

Here are some common questions that arise when considering a gunsmith torque wrench:

-

Q: What torque range do I need in a gunsmith torque wrench?

A: The ideal torque range depends on the firearms you work on. A range of 10-65 inch-pounds covers most common applications like scope mounting and action screw tightening. For larger caliber rifles, a wrench that extends to 80 or even 100 inch-pounds may be necessary. Always consult your firearm’s manufacturer specifications.

-

Q: How often should I calibrate my gunsmith torque wrench?

A: Calibration frequency depends on usage. For frequent use, calibrate every 6-12 months. For occasional use, annual calibration is sufficient. If the wrench is dropped or experiences unusual stress, calibrate immediately.

-

Q: Can I use a foot-pound torque wrench for inch-pound applications?

A: While technically possible with conversion, it’s highly discouraged. Foot-pound wrenches are less precise at lower torque values. Always use an inch-pound wrench for inch-pound applications to ensure accuracy.

-

Q: What’s the difference between a click-type and a digital torque wrench?

A: Click-type wrenches provide audible and tactile feedback when the set torque is reached. Digital wrenches display the torque value on a screen, offering higher accuracy and features like data logging. Digital wrenches are generally more expensive.

-

Q: What are the common mistakes to avoid when using a gunsmith torque wrench?

A: Common mistakes include failing to set the correct torque value, over-tightening fasteners, and using the wrong type of bit. Always double-check the torque specification and use the appropriate bit for the fastener.

-

Q: How do I properly store my gunsmith torque wrench?

A: Store your torque wrench in its case, set to its lowest torque setting, to release tension on the internal spring. This helps to maintain calibration accuracy and prolong the wrench’s lifespan.

-

Q: What is the best way to clean my gunsmith torque wrench?

A: Clean your torque wrench with a soft, dry cloth. Avoid using solvents or lubricants, as these can damage the internal components. Store in a dry place to prevent rust.

-

Q: Can I use a gunsmith torque wrench for automotive applications?

A: While some overlap exists, gunsmith torque wrenches are typically designed for lower torque values than automotive wrenches. Using a gunsmith wrench for high-torque automotive applications can damage the wrench and lead to inaccurate readings.

-

Q: How do I know if my gunsmith torque wrench is accurate?

A: The best way to ensure accuracy is to have your torque wrench calibrated by a professional calibration service. You can also purchase a torque tester to check the accuracy yourself.

-

Q: What are the benefits of using a torque wrench on scope rings?

A: Properly torquing scope rings prevents damage to the scope tube and ensures a secure and stable mount. This is crucial for maintaining accuracy and preventing the scope from shifting under recoil.

Investing in Precision: A Path to Superior Firearm Performance

In conclusion, mastering the art of torque application is essential for any serious gunsmith or firearm enthusiast. A quality gunsmith torque wrench, like the Wheeler FAT Wrench, provides the precision, control, and reliability needed to ensure optimal firearm performance, prevent damage, and enhance safety. By understanding the importance of torque and investing in the right tools, you can elevate your gunsmithing skills and enjoy the peace of mind that comes with knowing your firearms are properly maintained.

Now that you understand the importance of precise torque, explore our advanced guide to selecting the right scope mounts for your rifle and take your precision shooting to the next level.