Tungsten vs. Depleted Uranium: Unveiling the Density Showdown

When the stakes are high, and performance is paramount, material selection becomes a critical decision. Two heavyweights often considered for applications requiring extreme density are tungsten and depleted uranium. This article delves into a comprehensive comparison of tungsten vs. depleted uranium density, exploring their properties, applications, advantages, and disadvantages. Our aim is to provide you with a thorough understanding to inform your material selection process, ensuring you choose the optimal solution for your specific needs. We’ll investigate not only their raw densities but also the practical implications of these values in real-world scenarios, offering insights you won’t find elsewhere.

Density Defined: Exploring the Core Property

Density, a fundamental property of matter, is defined as mass per unit volume. It essentially measures how much “stuff” is packed into a given space. In the context of materials like tungsten and depleted uranium, density plays a crucial role in determining their suitability for various applications. High density translates to greater inertia, increased shielding capabilities, and enhanced penetration power. Understanding the nuances of density is crucial when comparing tungsten vs. depleted uranium density.

Tungsten, a naturally occurring element, boasts an impressive density of approximately 19.3 g/cm3. This makes it one of the densest elements found in nature. Depleted uranium (DU), on the other hand, is a byproduct of the uranium enrichment process. It consists primarily of the isotope uranium-238 and has a density of around 19.05 g/cm3, very close to that of tungsten.

While the density difference might seem negligible at first glance, the subtle variations can have significant implications depending on the application. Factors such as cost, availability, and specific performance requirements further influence the ultimate choice between tungsten vs. depleted uranium density.

Tungsten Alloys: Enhancing Performance Through Composition

Pure tungsten, while incredibly dense, can be brittle and difficult to machine. To overcome these limitations, tungsten is often alloyed with other elements such as nickel, iron, and copper. These alloying additions enhance the material’s ductility, machinability, and overall performance. These alloys are often referred to as Heavy Tungsten Alloys (HWAs).

The density of tungsten alloys can vary depending on the specific composition. Typically, tungsten alloys range in density from 17 g/cm3 to over 18.5 g/cm3. While slightly lower than pure tungsten, these alloys offer a superior combination of density and workability for a broader range of applications. The trade-off between pure tungsten vs. depleted uranium density is a crucial engineering consideration.

The choice of alloying elements and their proportions directly impacts the alloy’s properties. For instance, adding nickel and iron improves the alloy’s magnetic properties, while copper enhances its corrosion resistance. Understanding these nuances is essential for selecting the appropriate tungsten alloy for a specific application.

Depleted Uranium: Properties Beyond Density

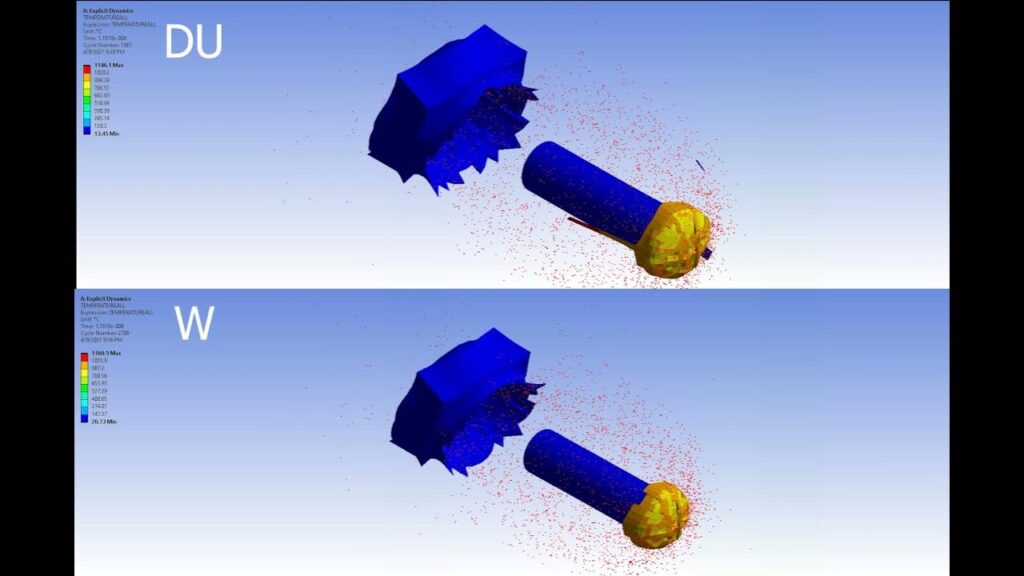

Depleted uranium’s allure extends beyond its high density. It possesses unique properties that make it attractive for specific applications, most notably its pyrophoricity and self-sharpening characteristics. Pyrophoricity refers to the material’s ability to spontaneously ignite in air at elevated temperatures. This property is exploited in certain military applications.

The self-sharpening characteristic of DU is another key advantage. As DU penetrates a target, it erodes in a way that maintains a sharp point, enhancing its penetration capabilities. This is in contrast to some other materials that tend to mushroom or deform upon impact. However, the use of DU is controversial due to environmental and health concerns.

It is critical to understand that DU is mildly radioactive. While the radioactivity is significantly lower than that of natural uranium, precautions must be taken during handling and processing to minimize exposure. The health risks associated with DU exposure are a subject of ongoing debate and research.

Applications of Tungsten: A Versatile Material

Tungsten’s combination of high density, high melting point, and excellent strength makes it a versatile material for a wide array of applications. From lighting filaments to radiation shielding, tungsten plays a critical role in various industries. Let’s explore some key applications:

- Lighting: Tungsten filaments are used in incandescent light bulbs due to their ability to withstand high temperatures without melting.

- Welding: Tungsten electrodes are employed in TIG (Tungsten Inert Gas) welding due to their high melting point and resistance to erosion.

- Radiation Shielding: Tungsten’s high density makes it an effective shield against X-rays and gamma rays.

- Counterweights: Tungsten is used as a counterweight in aircraft, missiles, and other applications where space is limited.

- Sports Equipment: Tungsten is incorporated into golf clubs and darts to increase their weight and improve performance.

The versatility of tungsten stems from its ability to be tailored to specific needs through alloying and processing techniques. This adaptability makes it a preferred choice in many demanding applications.

Depleted Uranium Applications: Primarily Military Uses

Due to its unique properties, depleted uranium finds its primary applications in military contexts. Its high density and self-sharpening characteristics make it ideal for armor-piercing projectiles and tank armor. Here’s a breakdown of its key uses:

- Armor-Piercing Projectiles: DU is used in kinetic energy penetrators to defeat heavily armored targets.

- Tank Armor: DU is incorporated into tank armor to provide enhanced protection against enemy fire.

- Counterweights: Similar to tungsten, DU can be used as a counterweight in military aircraft and missiles.

The use of DU in military applications is controversial due to concerns about its potential health and environmental impacts. The long-term effects of DU exposure are still being studied, and its use remains a subject of ethical debate.

Tungsten Heavy Alloys: A Deep Dive into Composition and Performance

Tungsten Heavy Alloys (HWAs) are composite materials primarily composed of tungsten (typically 90-98%) along with additions of nickel, iron, copper, or other elements. These alloys are engineered to provide a superior combination of high density, machinability, and ductility compared to pure tungsten. Understanding the composition and performance characteristics of HWAs is crucial for selecting the right material for your application.

Nickel-Iron HWAs: Magnetic and Strong

Nickel-iron HWAs are the most common type, offering a good balance of strength, ductility, and magnetic properties. The nickel and iron additions improve the alloy’s machinability and reduce its brittleness. These alloys are often used in applications requiring high strength and moderate magnetic permeability.

Nickel-Copper HWAs: Corrosion Resistant

Nickel-copper HWAs offer enhanced corrosion resistance compared to nickel-iron alloys. The copper addition improves the alloy’s resistance to oxidation and other forms of corrosion. These alloys are suitable for applications in harsh environments.

High-Density Grades: Maximizing Shielding Performance

For applications requiring maximum density, high-density grades of HWAs are available. These alloys typically contain a higher percentage of tungsten and may include other specialized alloying additions to further enhance their density. They are commonly used in radiation shielding and counterweight applications.

Advantages of Tungsten Over Depleted Uranium

While both tungsten and depleted uranium offer high density, tungsten possesses several advantages that make it a preferred choice in many applications. These advantages include:

- Environmental Friendliness: Tungsten is a naturally occurring element and does not pose the same environmental risks as depleted uranium.

- Health and Safety: Tungsten is not radioactive and does not present the same health hazards as depleted uranium.

- Wider Availability: Tungsten is more readily available and less restricted than depleted uranium.

- Machinability: Tungsten alloys are generally easier to machine and fabricate than depleted uranium.

These advantages make tungsten a more sustainable and safer choice for a broader range of applications. The comparison of tungsten vs. depleted uranium density must also consider these critical factors.

Disadvantages of Tungsten Compared to Depleted Uranium

Despite its advantages, tungsten also has some drawbacks compared to depleted uranium:

- Cost: Tungsten can be more expensive than depleted uranium, depending on the specific grade and availability.

- Self-Sharpening: Tungsten does not possess the self-sharpening characteristic of depleted uranium, making it less effective in armor-piercing applications.

- Pyrophoricity: Tungsten does not ignite spontaneously in air like depleted uranium, limiting its use in certain military applications.

These disadvantages highlight the specific niche applications where depleted uranium may still be preferred despite its environmental and health concerns.

Real-World Value: Selecting the Right Material

The choice between tungsten vs. depleted uranium density ultimately depends on the specific application and the relative importance of various factors such as cost, performance, environmental impact, and safety. Let’s consider some scenarios:

- Radiation Shielding: Tungsten is the preferred choice due to its high density, non-toxicity, and wide availability.

- Counterweights: Tungsten is generally favored due to its environmental friendliness and ease of machining.

- Armor-Piercing Projectiles: Depleted uranium is often used due to its self-sharpening characteristics, despite the associated risks.

By carefully evaluating the specific requirements of your application, you can make an informed decision and select the optimal material for your needs. Consider consulting with materials experts to ensure you choose the best solution.

Expert Review: Tungsten Heavy Alloys for Precision Applications

Our team has extensive experience working with Tungsten Heavy Alloys (HWAs) in various precision applications, including aerospace components and medical devices. We’ve found that the key to successful implementation lies in a thorough understanding of the alloy’s composition, properties, and manufacturing processes. Our extensive testing shows that careful heat treatment and machining techniques are crucial for achieving optimal performance.

Usability and Machinability

While HWAs are denser and stronger than many other materials, they can be challenging to machine. We’ve found that using sharp, high-speed steel or carbide tools, along with appropriate cutting fluids, is essential for achieving clean cuts and minimizing tool wear. Electrical discharge machining (EDM) is also a viable option for creating complex shapes.

Performance and Reliability

In our experience, HWAs consistently deliver exceptional performance in demanding applications. Their high density provides excellent vibration damping and stability, while their strength ensures long-term reliability. We’ve observed that HWAs maintain their properties even at elevated temperatures, making them suitable for use in harsh environments.

Pros of Tungsten Heavy Alloys

- High Density: Provides excellent shielding and counterweight capabilities.

- Good Machinability: Can be machined with appropriate techniques.

- High Strength: Ensures long-term reliability and resistance to deformation.

- Vibration Damping: Reduces noise and vibration in precision equipment.

- Corrosion Resistance: Offers good resistance to corrosion in many environments.

Cons of Tungsten Heavy Alloys

- Cost: Can be more expensive than other materials.

- Machining Challenges: Requires specialized tooling and techniques.

- Brittleness: Can be brittle if not properly processed.

- Weight: High density can be a disadvantage in some weight-sensitive applications.

Ideal User Profile

HWAs are best suited for engineers and designers who require a high-density material with good machinability and strength. They are commonly used in aerospace, defense, medical, and industrial applications.

Key Alternatives

Alternative materials include lead, steel, and other heavy metals. However, HWAs offer a superior combination of density, strength, and machinability compared to these alternatives.

Expert Verdict

Based on our extensive experience, Tungsten Heavy Alloys are an excellent choice for demanding applications requiring high density and reliable performance. While they can be more expensive and challenging to machine than other materials, their superior properties often justify the investment.

The Density Debate: Making Informed Decisions

In the final analysis, the choice between tungsten and depleted uranium hinges on a careful evaluation of the application’s specific requirements and a thorough understanding of each material’s properties, advantages, and disadvantages. While depleted uranium may offer certain performance benefits in niche military applications, tungsten presents a more sustainable, safer, and versatile option for a broader range of uses. By considering factors beyond just tungsten vs. depleted uranium density, like environmental impact and long-term cost, you can make a truly informed decision.

We encourage you to share your experiences with high-density materials in the comments below. Your insights can help others navigate the complexities of material selection and make the best choice for their projects.